These types of specimen tests are commonly used to determine the key properties of a material, such as tensile strength, Izod and Charpy impact strength, hardness, flammability, shrinkage and gloss/color matching.

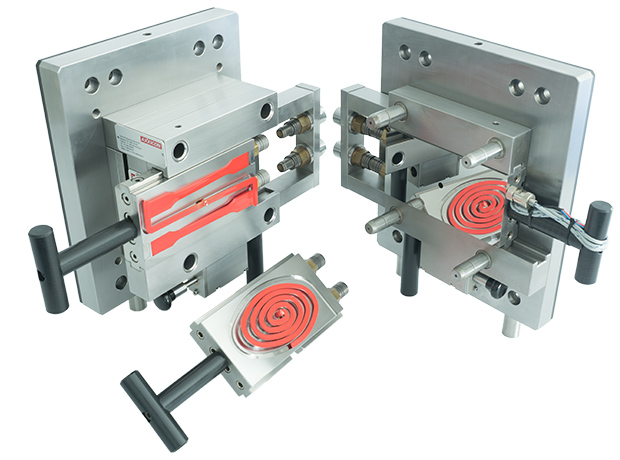

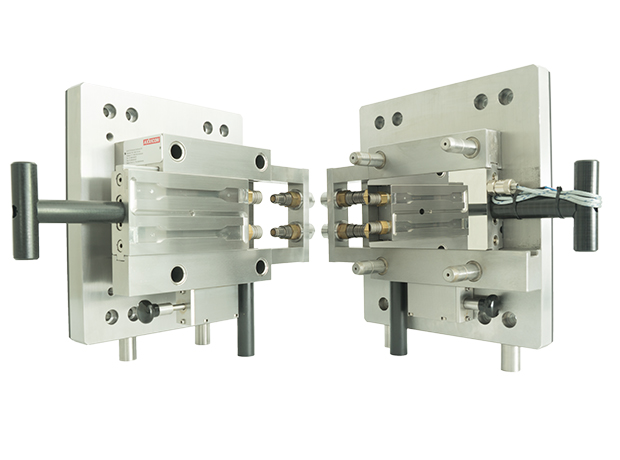

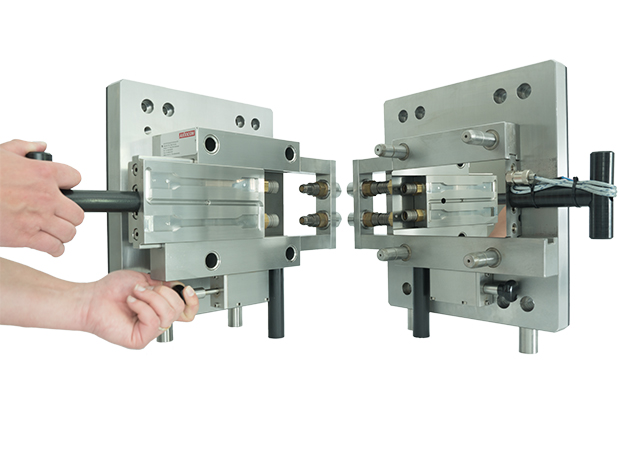

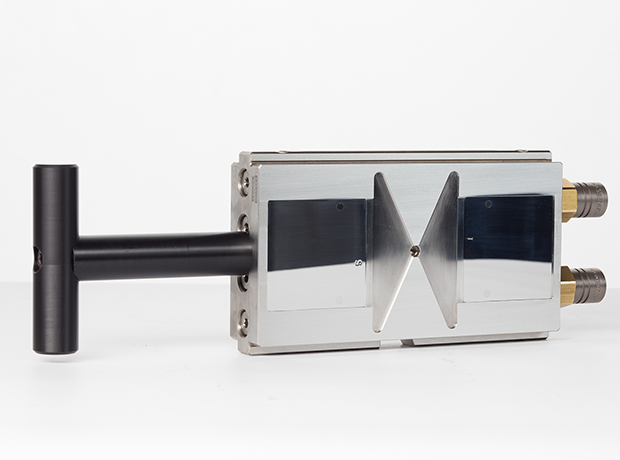

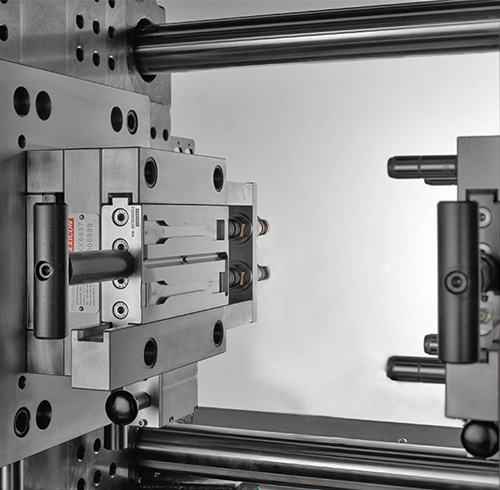

The AIM™ Quick Change Mold is available in three sizes: Standard, XL and XXL. The mold base hole pattern comes in Euromap, SPI or customer-specific design.

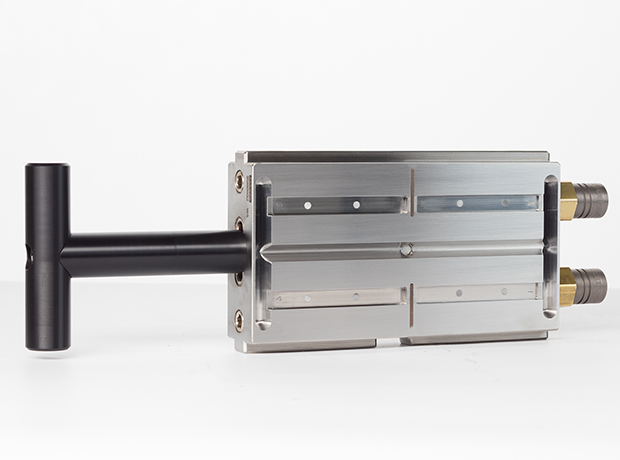

The most common inserts include ISO A (specimen 170 x 10 x 4mm), ISO B (specimen 80 x 10 x 4mm), ISO D2 (specimen 60 x 60 x 2mm) and spiral flow.

The AIM Quick Change Mold fully complies with all the requirements for an ASTM or ISO approved injection mold, with strong emphasis being placed on greater standardisation and uniformity of specimen tests.

Features & Benefits

Mold Specifications

Standard:

XL:

XXL:

Model MP1200

Model MP1200

Model 1ST

Model 1ST

Model 5ST

Model 5ST

Model 10ST

Model 10ST

Model 5KL

Model 5KL

Model 10kL

Model 10kL

Model 25kL

Model 25kL