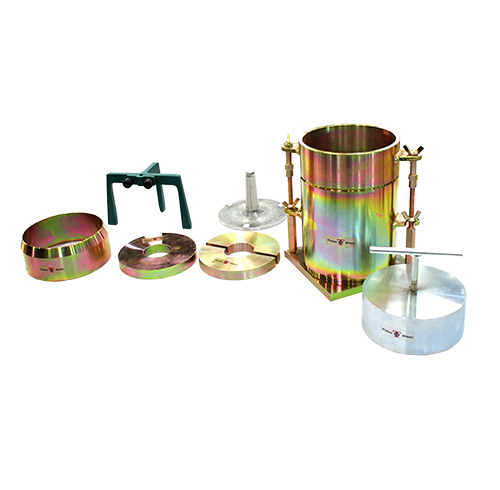

The California Bearing Ratio test (usually called CBR test) is an empirical test developed in California, USA. It determines the relative bearing ratio and expansion characteristics under known surcharge weight of base, subbase and sub grade soils for the design of roads, pavements and runways. The CBR test is used extensively in selection of materials and control of sub grades.

The test can be performed in the laboratory on prepared samples or in-situ on location. Because of the empirical nature of the test, it is valid only for the application for which it was developed: the design of highway base thicknesses.

This load frame is designed for conducting unconfined, triaxial, CBR and other routine tests.

The loading system comprises of a screw jack with detachable handle. The lower platen moves up and down. The top bracket is adjustable for vertical clearance and has an adaptor for connecting standard proving rings. A dial gage mounting bracket is provided on one of the two pillars. Rate of strain: 1.00 and 1.27mm/min.

Features & Benefits

Specifications

Note: This test, being of an empirical nature, is valid only for the application for which it was developed: the design of highway base thicknesses.

CBR Test Apparatus – Analog

CBR Test Apparatus – Analog