Tinius Olsen

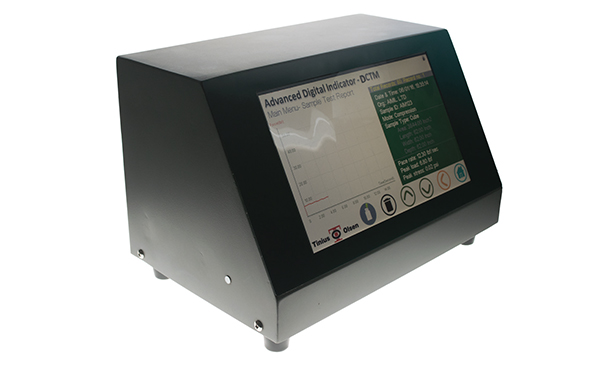

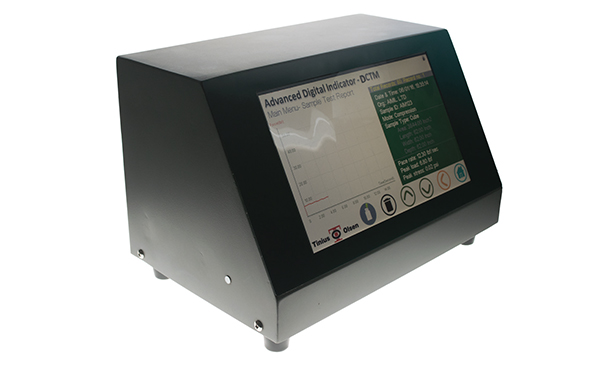

Touchscreen-Based EDI

Features & Benefits

- Touchscreen TFT with 800 x 480 pixels

- Icon driven software showing figures and diagrams for ease of use

- Unique data storage options with both internal storage (of 200 tests) and direct to USB thumb drive storage

- Separate USB port to communicate with Horizon software (only applicable to our Fully Automatic {FA} models)

- Optional integrated thermal printer

- Simultaneous display of load vs time graph, stress and actual load rate

Specifications

- Required or option: Option

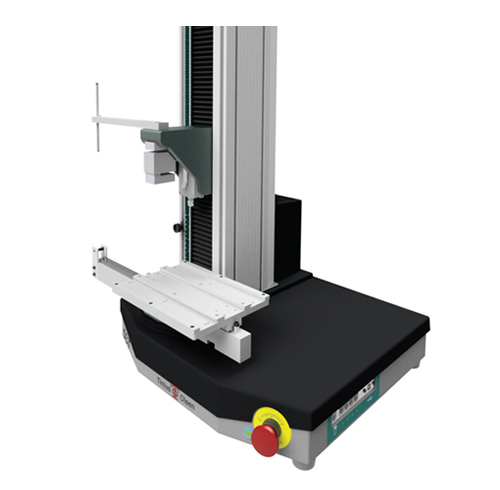

- Compatible with TO: DG and FA series frames

- Touchscreen: Multi-touch capacitive, rain resistant and inductive stylus

- Color: Yes

- Dedicated hard keys: Cross-head positioning

- Technology platform: Android v4.1.1

- Display: 141mm diagonal super AMOLED 720*1280 pixels

- Contrast ratio: 402 nominal, 2.307:1 sunlight

- IP rating: Sealed to IP67 (submersible)

- Shock vibration rating: MIL-STD 810G Method 516.6 & Method 514.6

- Size (LxWxD): 232 x 99 x 29mm/9.1 x 3.9 x 1.14in

- Weight: 44g/15.6oz

- Operating temperature: 10-40°C

- Storage temperature: 5-45°C

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

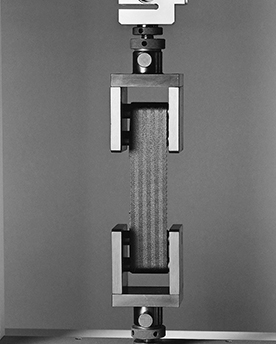

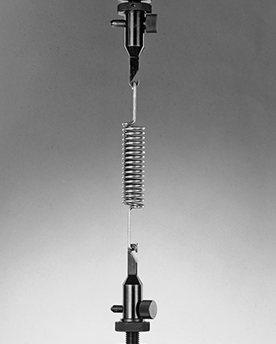

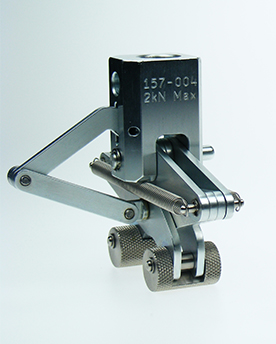

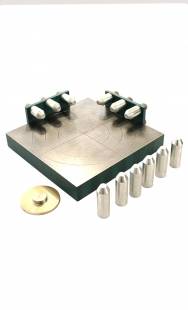

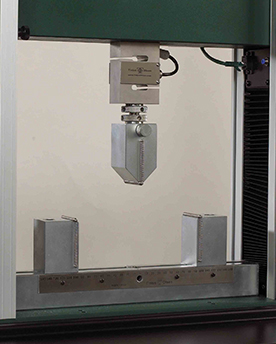

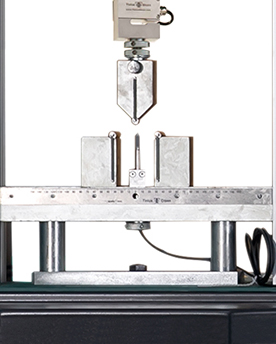

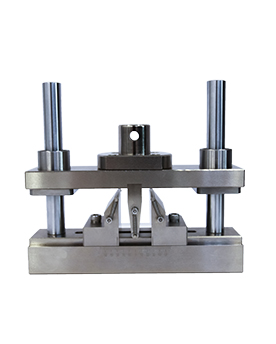

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

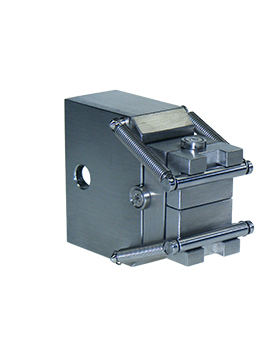

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

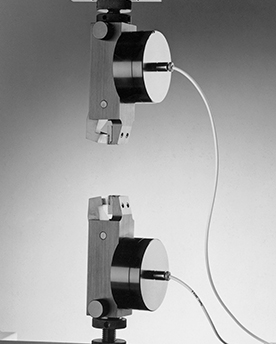

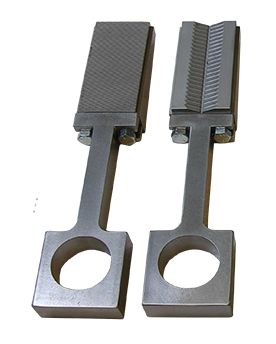

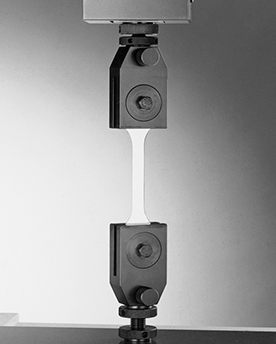

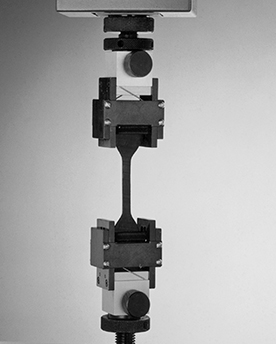

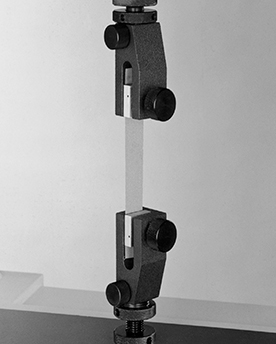

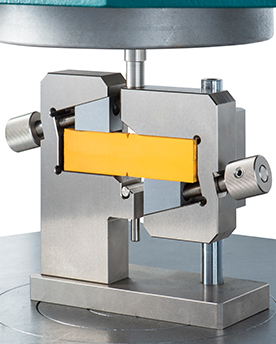

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

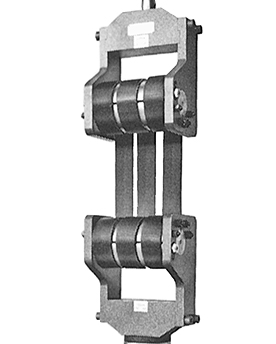

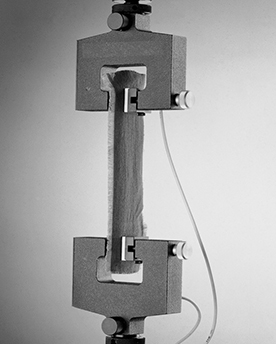

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

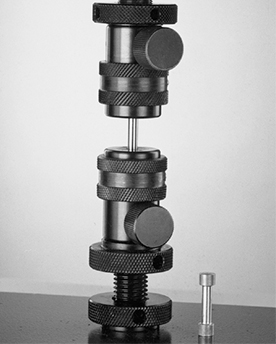

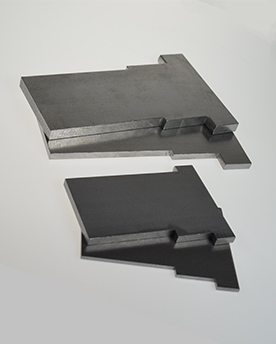

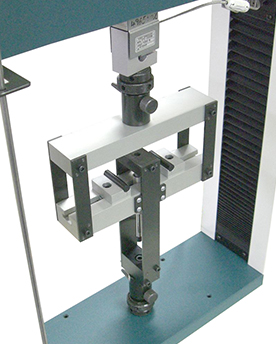

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

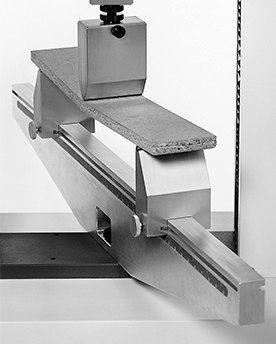

Shear Loading Compression Fixture

Shear Loading Compression Fixture

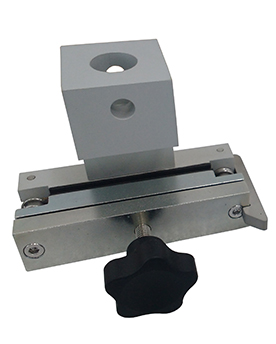

Specimen Identification Station

Specimen Identification Station

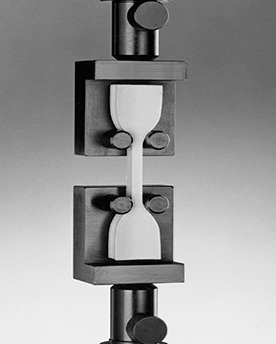

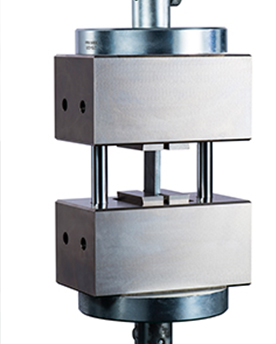

Combined Loading Compression Fixture

Combined Loading Compression Fixture

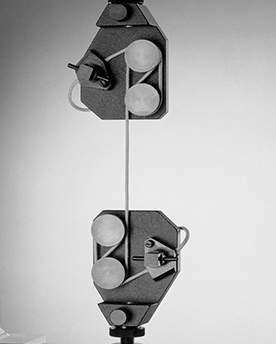

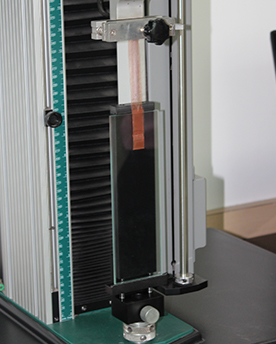

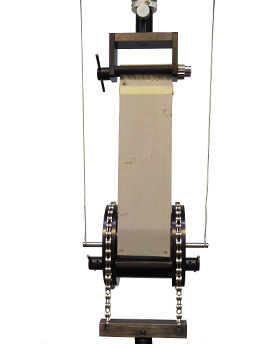

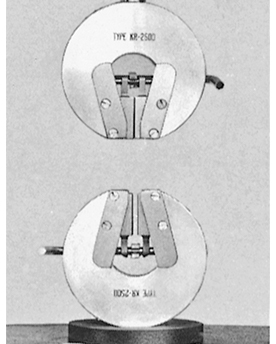

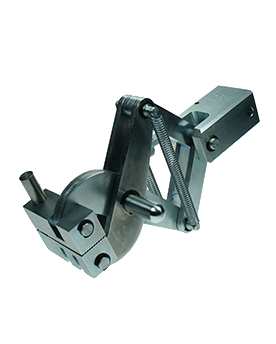

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

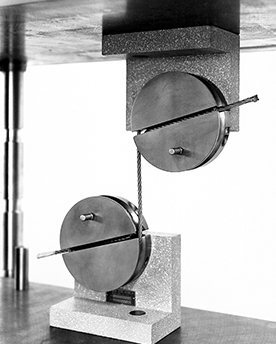

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN