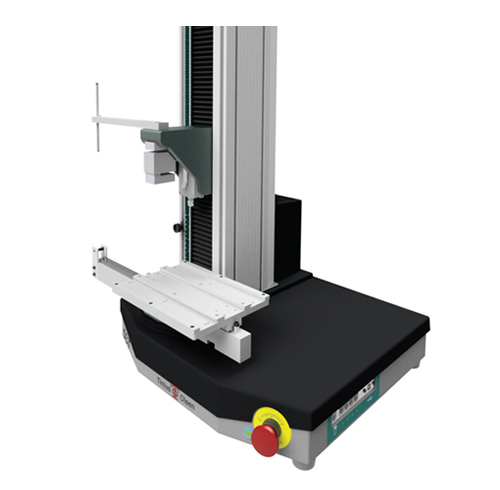

Tinius Olsen

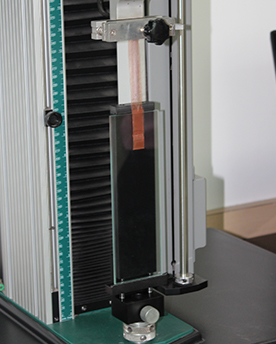

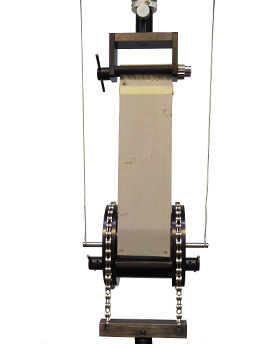

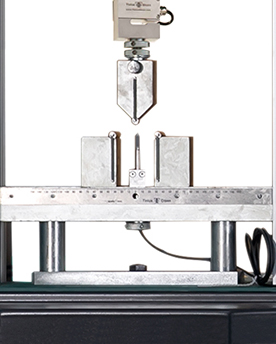

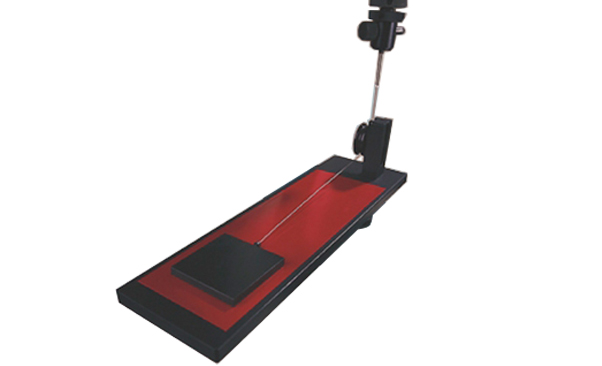

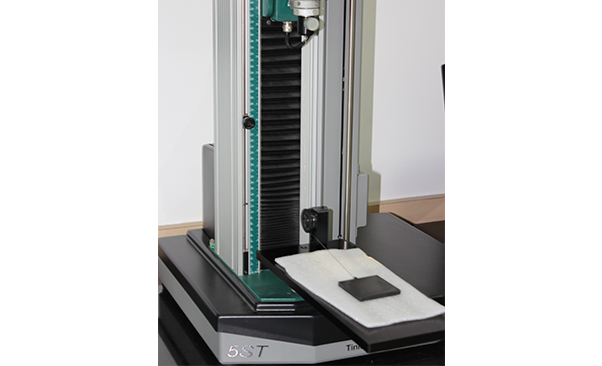

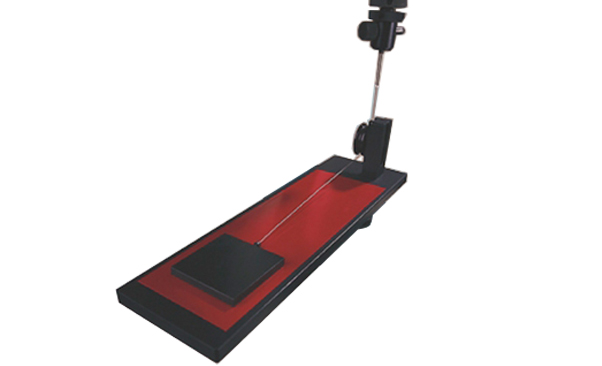

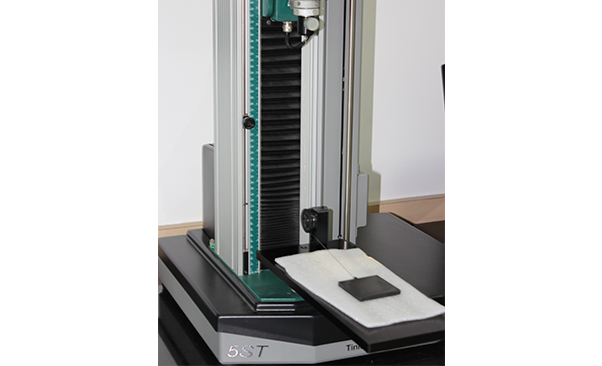

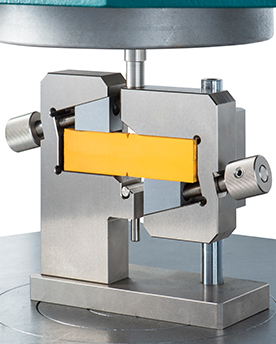

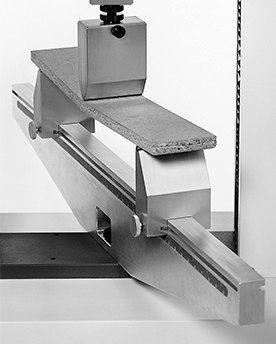

Coefficient of Friction Test

Specifications

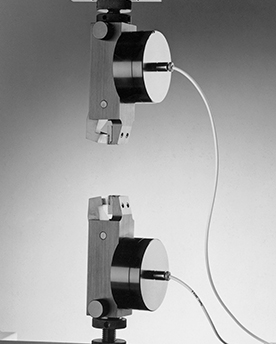

- Maximum capacity: 25N/5.6lbf

- Minimum loadcell: 5N/1lbf

- Maximum support bed width: 100mm/4in

- Support bed length: 300mm/12in

- Sled weight: 200g +/- 2g

- Temperature limits: Ambient to 28°C

Applications

Flexible pressure sensitive tapes, labels and laminated coatings. Typical test standards include ASTM D1894, ISO 8295 and more.

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

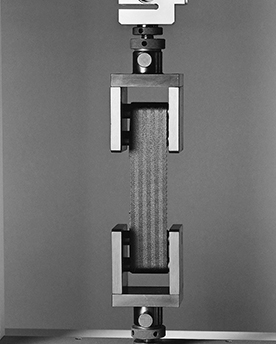

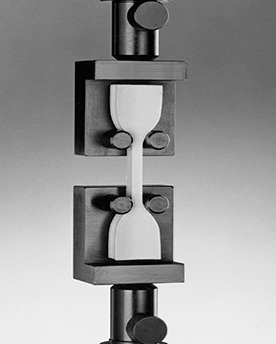

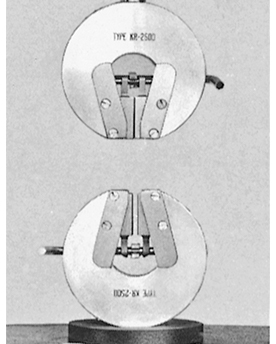

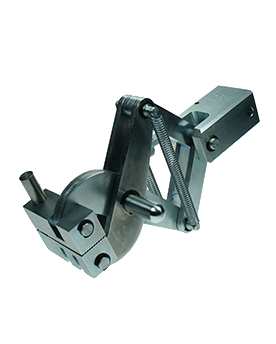

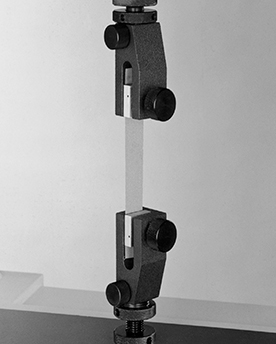

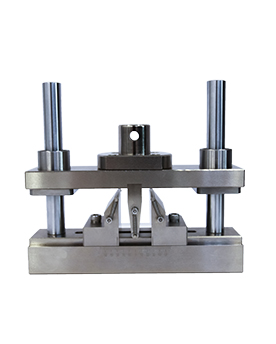

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

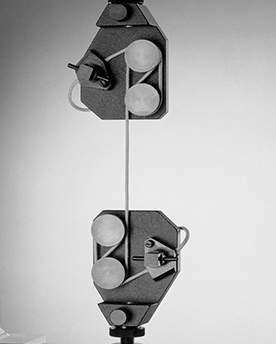

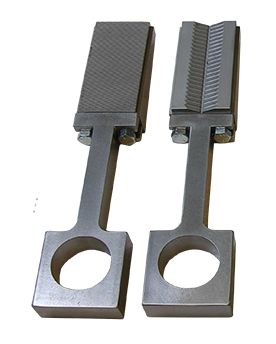

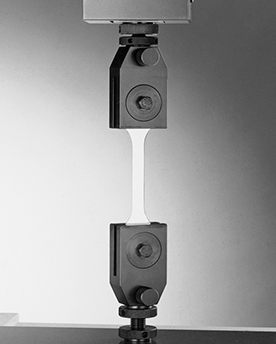

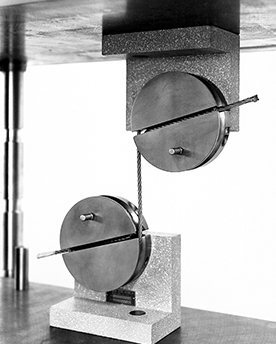

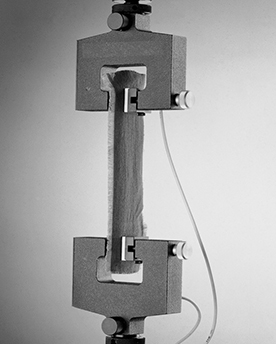

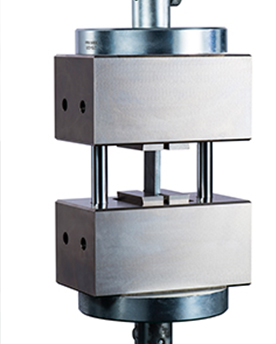

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

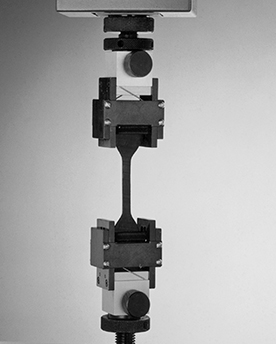

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

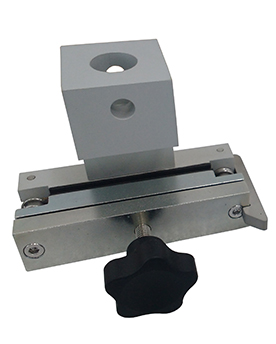

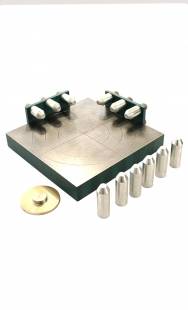

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

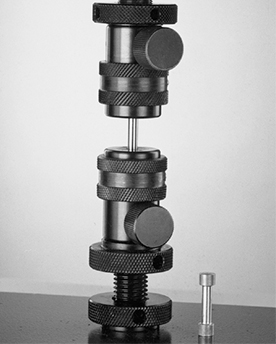

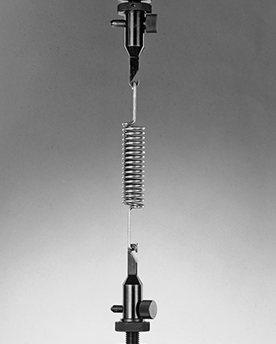

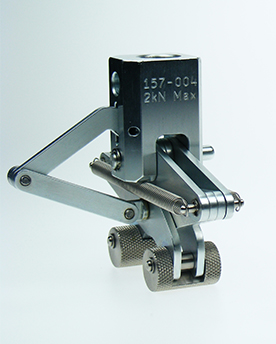

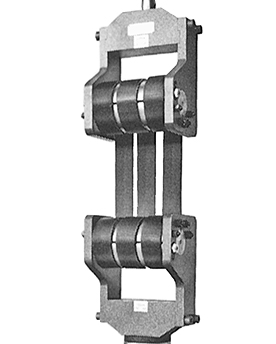

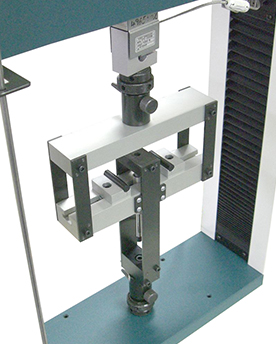

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

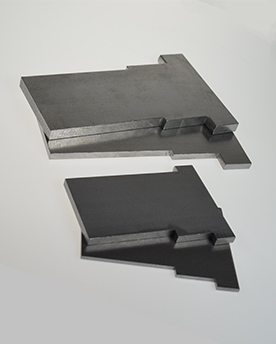

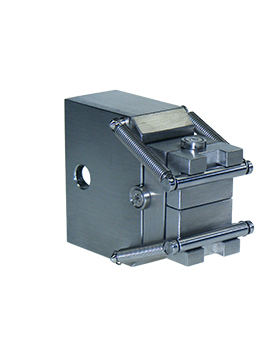

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

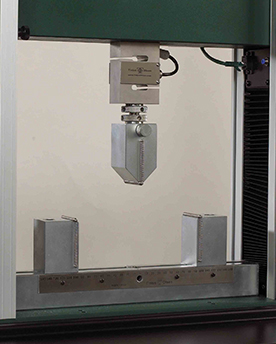

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN