Tinius Olsen

Proterm

Two models of this tethered controller are available: one designed for the operation with ST series testers, and one designed for operation with SL series testers.

Features & Benefits

- SL model has five more buttons than the ST model, which are used for opening and closing hydraulic actuated lever pocket wedge grips, and for moving the motorized crosshead on hydraulic machines

- Interface is surrounded by silicone rubber guard to prevent damage

- Keys made from robust elastomeric epoxy and safe in all kinds of environments

- Keypad surface provides superior splash resistance, which reduces curling and peeling and makes it ideal for all kinds of operating environments.

Specifications

Specifications apply to both SL Series Handheld User Interfaces and ST Series Handheld User Interfaces, except where indicated

- Required or option: Option in support of testing machine crosshead positioning, specimen insertion and monitoring of machine status. Cannot be used to perform materials testing

- Compatible with TO: ST series frames and SL series frames

- Tactile push-button type: Black elastomeric keys with epoxy caps. The keypad surface provides excellent splash resistance with no curling or peeling of the keypad overlay

- Dedicated hard keys: SL Series – 18 keys, ST Series – 13 keys

- Technology platform: Embedded processor-based

- Language: Supports global language character sets

- Screen: Monochrome supertwist LCD5 – 5 lines (3 live sources, 2 status lines)

- Screen size: 192 x 128 pixels

- IP rating: Sealed to IP51 (drip-proof)

- Size (LxWxD): 209 x 104.1 x 29.2mm/8.25 x 4.10 x 1.15in

- Weight: 340g/12oz

- Graphics: ASCII character set, dark characters on light background with blinking and inverse video attributes

- Cable connection: 6-pin modular interface connector capable of communication up to 57,600bps

- Cradle mount to frame: SL series – mounted on adjustable, articulated arm fixed on console; ST Series – mounted on adjustable, articulated arm which in turn is connected to T slot mounting point on test frame

- Cable length: 600mm/23.6in

- Surround: Case is molded from Cycolac ABS® with a silicon rubber surround

- Power requirement: Via RS232 cable

- Operating temperature: 10-40°C

- Operating humidity: 10-90% non-condensing

- Storage temperature: 5-35°C

- Storage humidity: 10-70% non-condensing

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

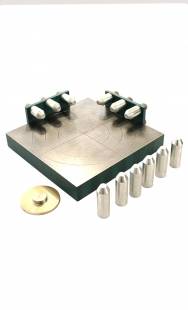

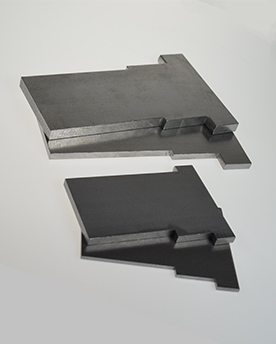

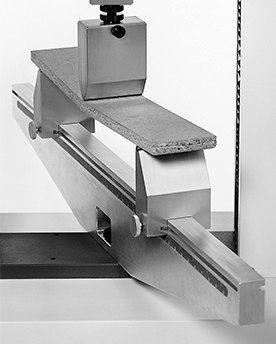

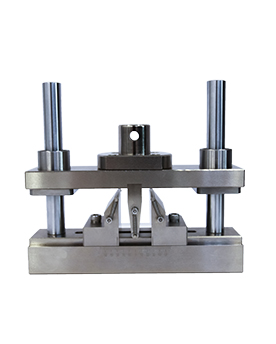

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

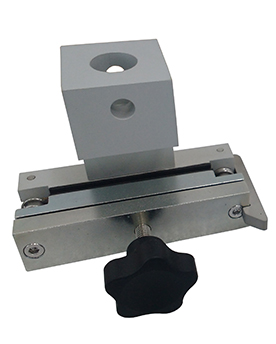

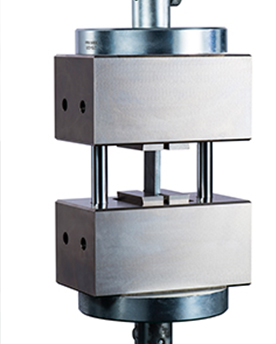

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

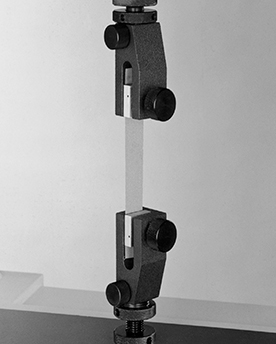

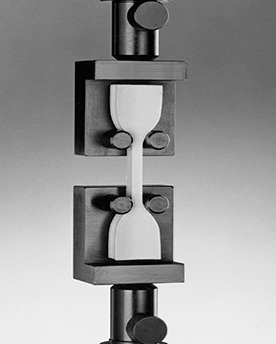

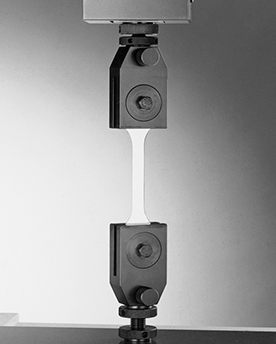

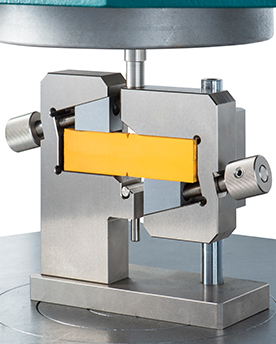

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN

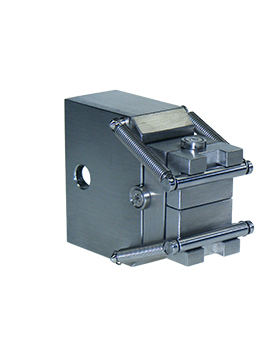

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

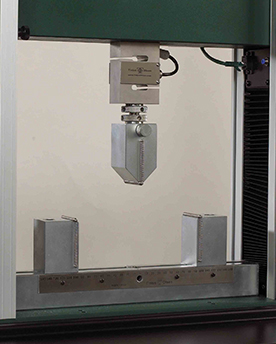

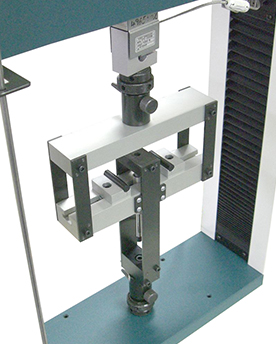

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

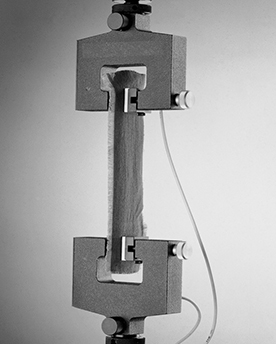

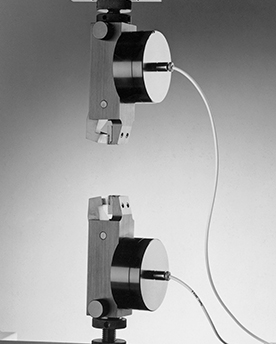

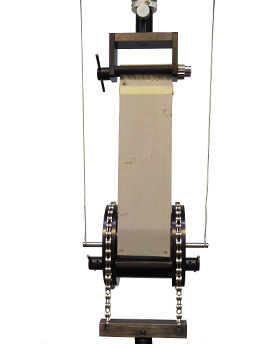

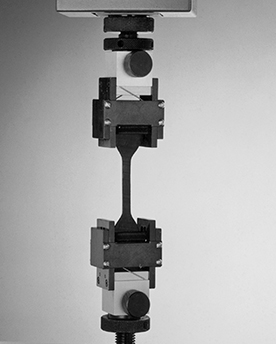

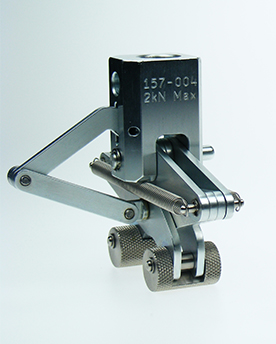

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

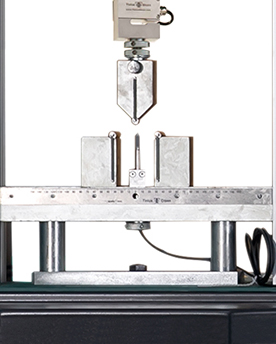

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

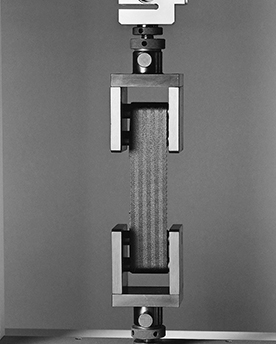

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

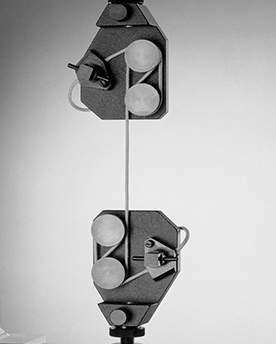

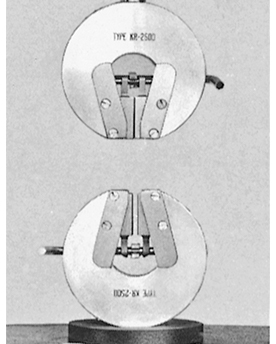

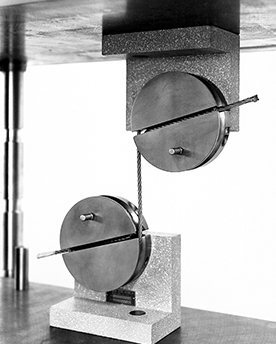

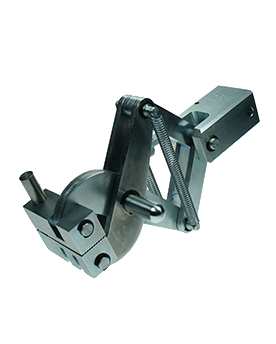

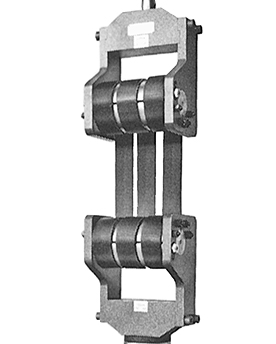

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips