Tinius Olsen

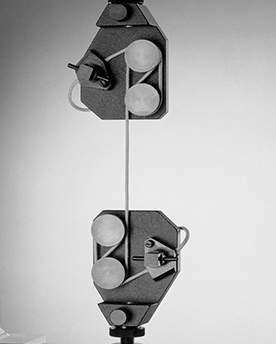

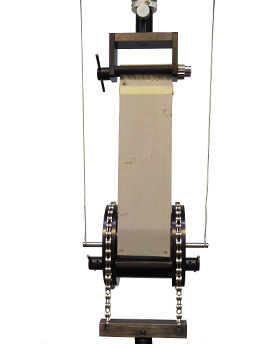

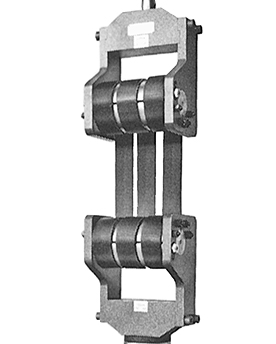

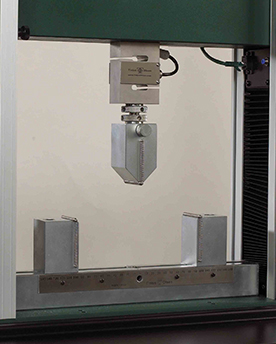

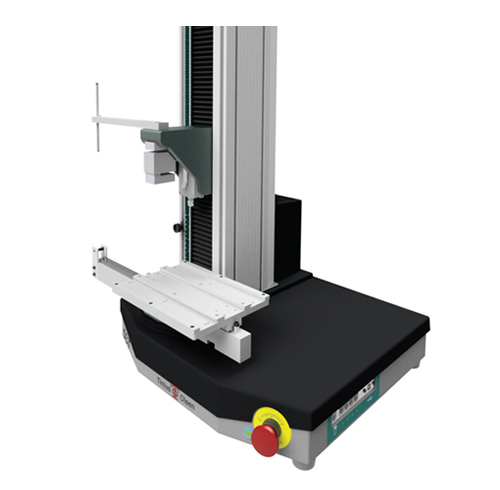

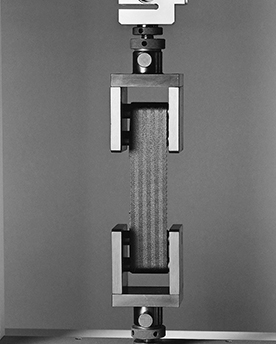

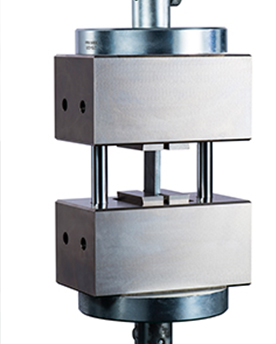

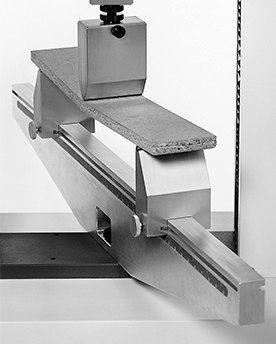

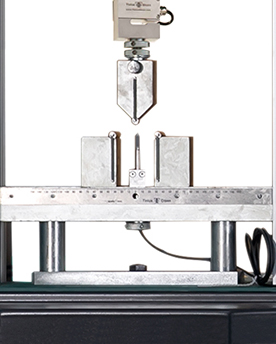

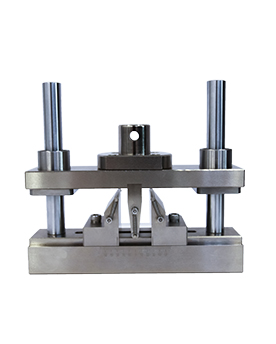

Flexural Frame

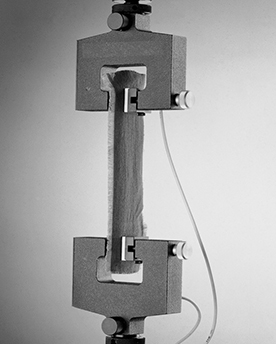

On a specimen beam ideally of 150 x 150 x 750mm and/or 100 x 100 x 500mm, the maximum tensile stress reach at the bottom of the test beam is considered as the Flexural Strength/Modulus of Rupture of the material.

Key Features

- Applicable Standards: BS 1881, ASTM C 78-02, BS EN 12390-5:2000

- Lightweight, rugged high strength frame

- Self-aligning four-point loading roller assembly

- Maximum capacity of either frame is 100kN/22,000lbf

- For testing beams of 100 x 100 x 500mm and 150 x 150 x 700mm

Ordering Information

- TO-33101-ASTM Flexure Testing Frame 100kN machine no pump for use with CTMs using 2-way valve

- TO-33101-BS Flexure Testing Frame 100kN machine no pump for use with CTMs using 2-way valve

- TO-331-ASTM Flexure Testing Manual Machine ECO, for 10 x 10 x 50cm & 15 x 15 x 70cm beams

- TO-331-BS Flexure Testing Manual Machine ECO, for 10 x 10 x 50cm & 15 x 15 x 70cm beams

- TO-332-ASTM-01 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 110V, 60Hz

- TO-332-ASTM-02 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 220V, 60Hz

- TO-332-ASTM-03 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 220V, 50Hz

- TO-332-BS-01 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 110V, 60Hz

- TO-332-BS-02 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 220V, 60Hz

- TO-332-BS-03 Flexure Testing Machine, 100kN, for 10 x 10 x 50cm & 15 x 15 x 70cm beams EDI, 220V, 50Hz

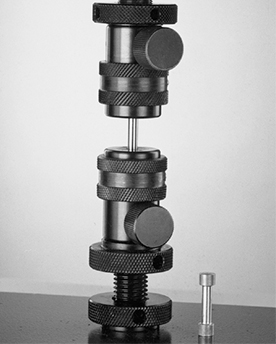

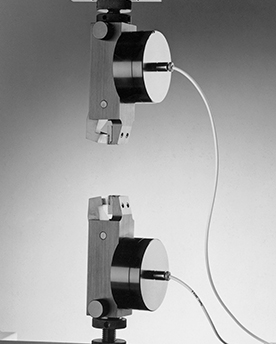

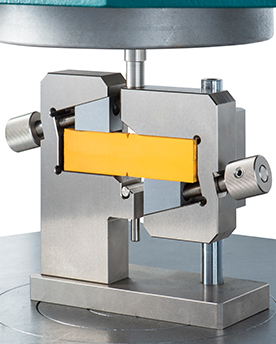

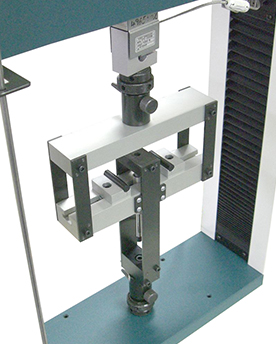

Key Features

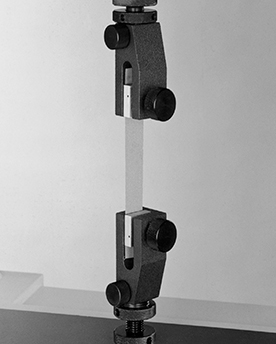

- Non-contacting video extensometer solution

- One extensometer measures in tension, compression, flexural, shear modes

- No need for bonded strain gauges, multiple clip-on extensometers for r&n

- Supports axial, transverse, orthogonal and rotational measurements

- Provides a permanent record for recall of the test in video format with full resolution embedded strain data

- Meets the requirements of ISO 9513 class 0.5, ASTM E83 class B1 and GB

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

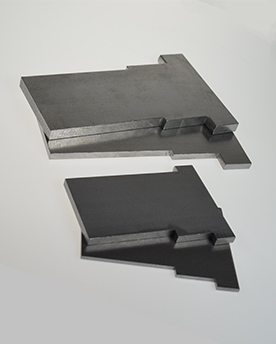

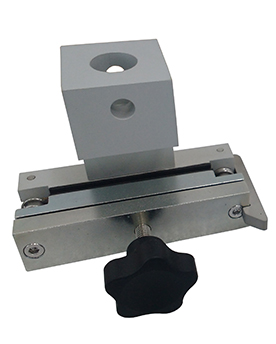

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

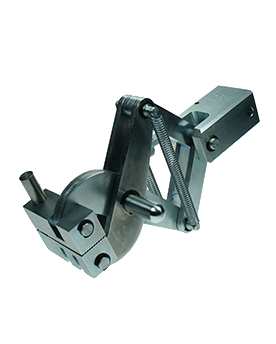

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

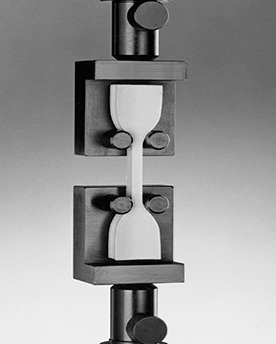

Combined Loading Compression Fixture

Combined Loading Compression Fixture

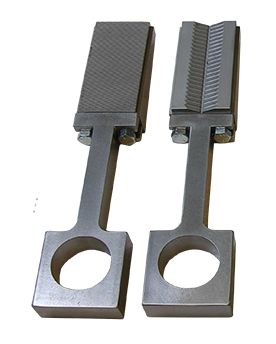

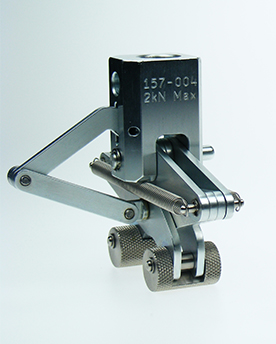

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

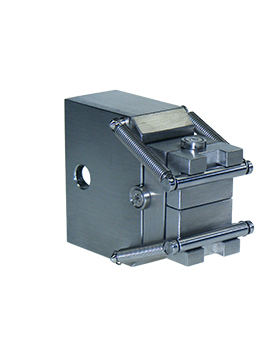

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

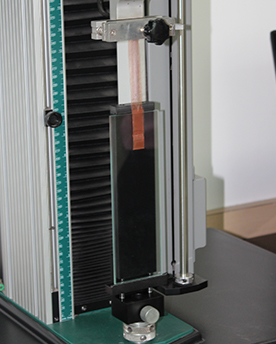

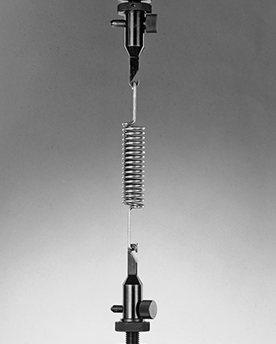

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture