Tinius Olsen

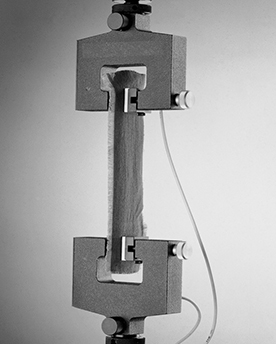

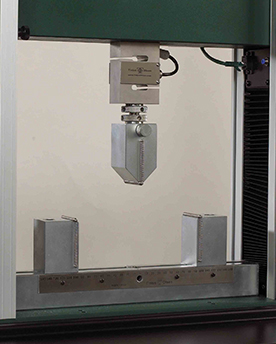

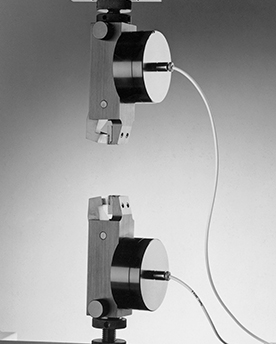

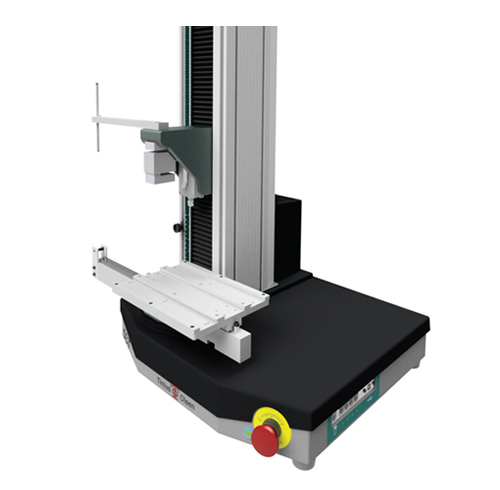

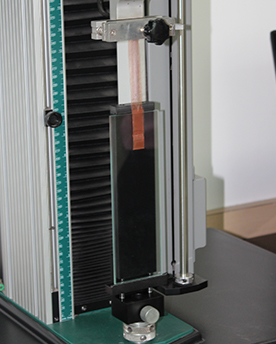

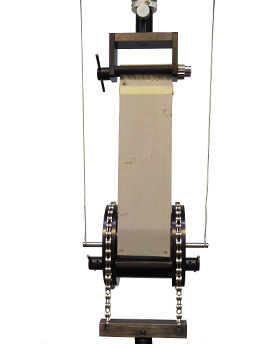

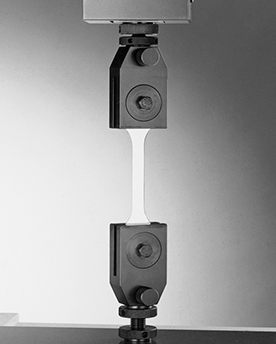

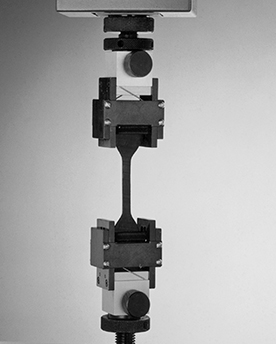

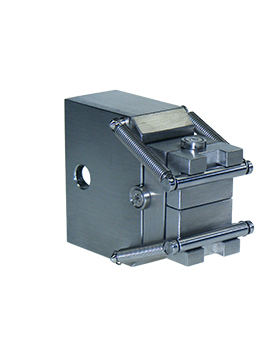

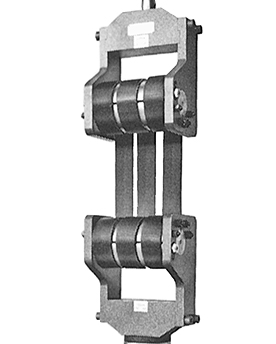

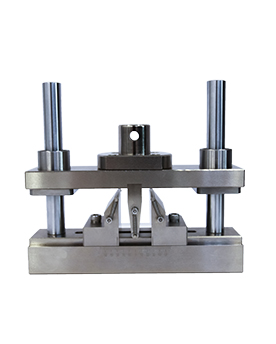

300kN Hydraulic Tensile Grip

Applications

Specifications

*Alternate wedge widths available

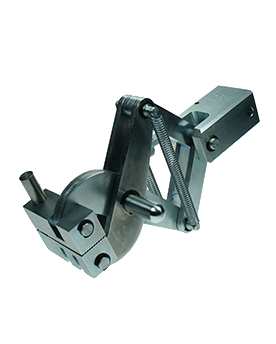

Required accessories (see below)

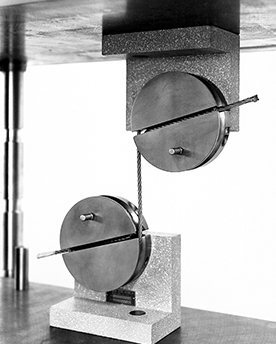

Hydraulic pumping unit

Hydraulic pumping unit (ref. 01036002) with grip control for use with the 300kN grips (ref. 01036030).

Specifications

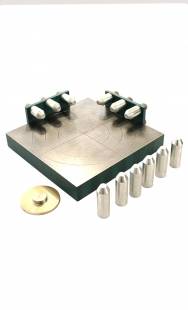

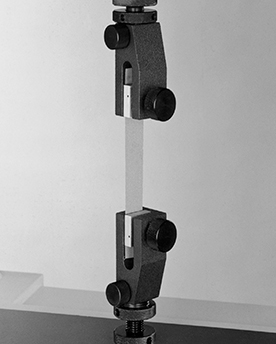

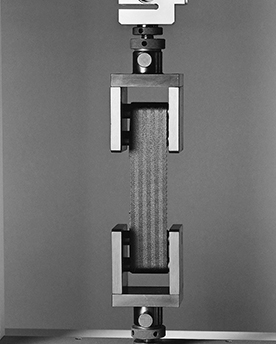

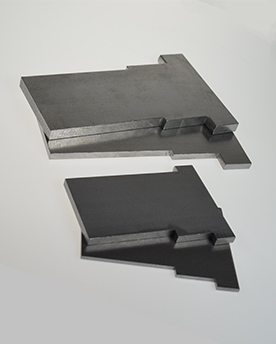

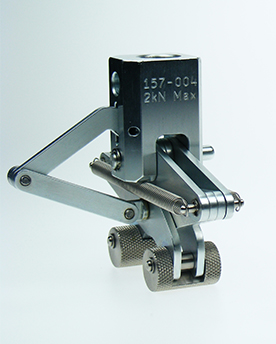

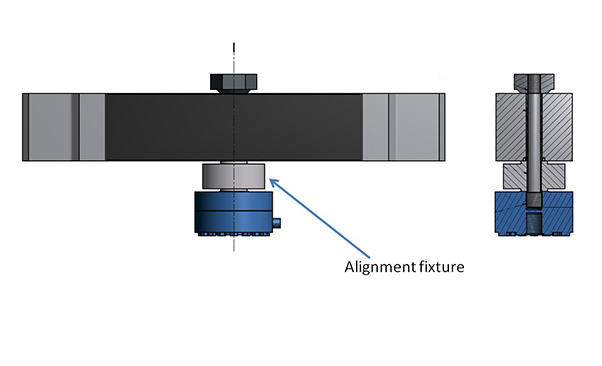

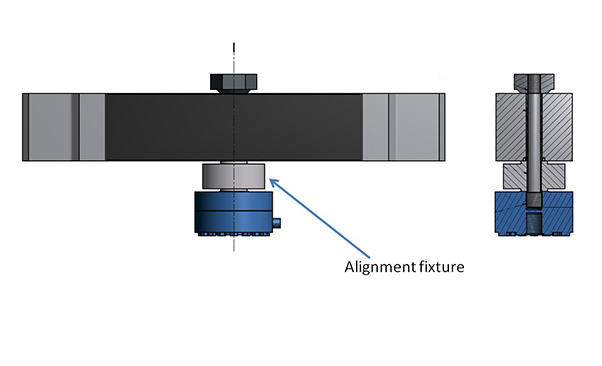

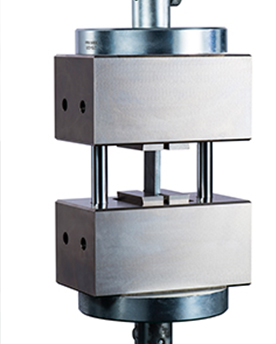

Alignment fixture and grip faces

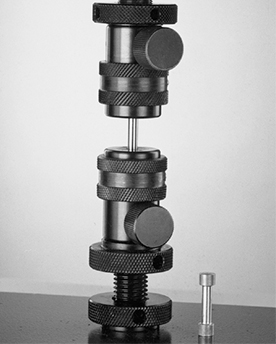

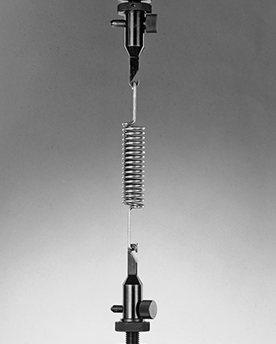

Alignment fixture (ref. 01036004)

This allows alignment adjustment to eliminate loading inconsistencies and inaccuracies that frequently occur during sample loading. It has a maximum capacity of 300kN/60klbf.

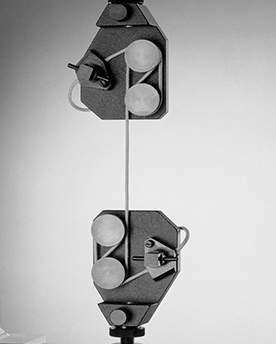

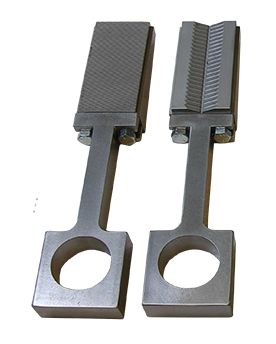

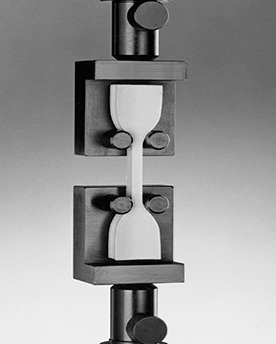

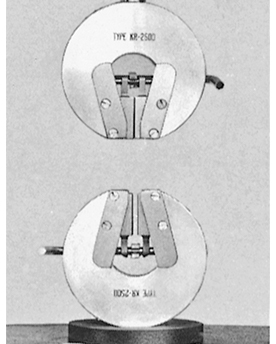

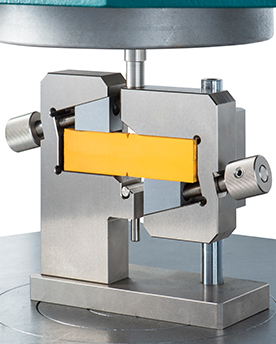

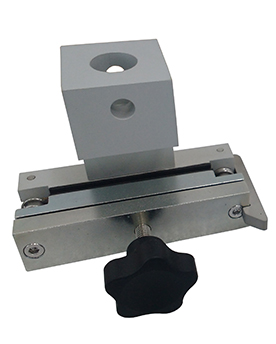

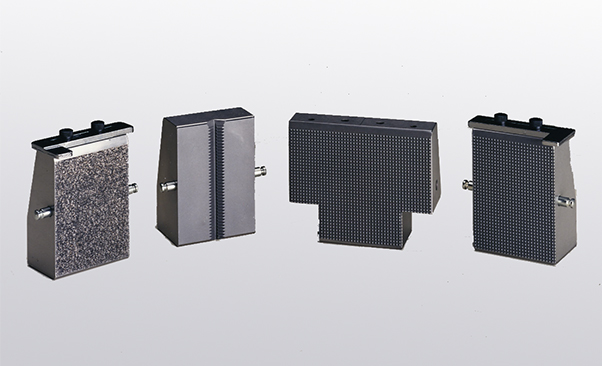

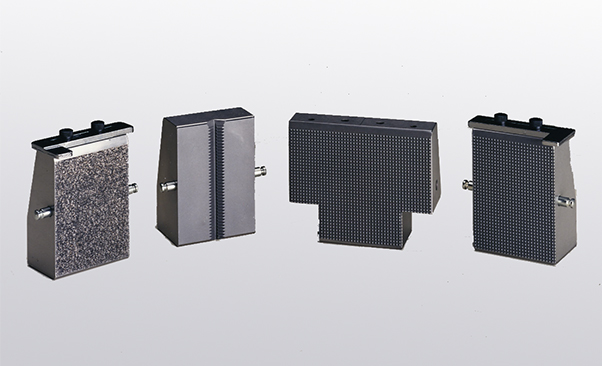

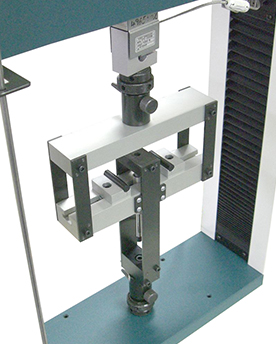

Wedge grip faces

These are used in the side loading hydraulic wedge grip body and are available in a variety of different shapes that best match the specimen profile.

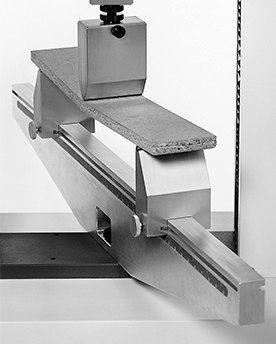

Flat wedge specimens

Specimen thickness:

Narrow wedge set

Wedge width: 50.8mm /2in

Wide wedge set

Wedge width: 101.6mm /4.00in

Round wedge specimens

Specimen diameter: 15,20,30mm/0.75,1.0,1.2in

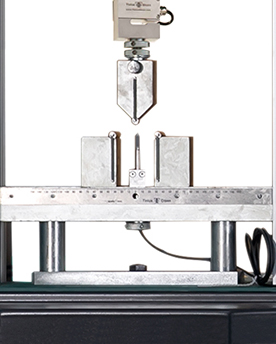

Vee wedge specimens

Specimen diameter:

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips