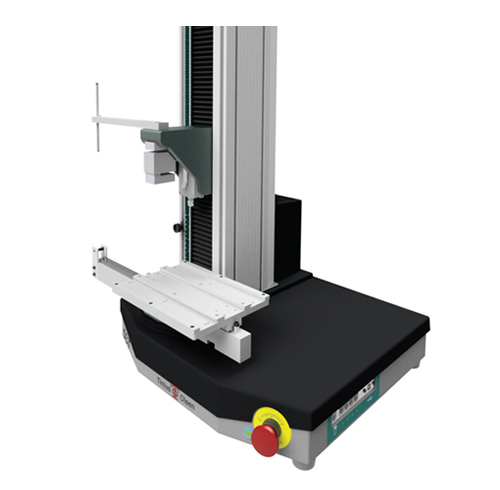

Tinius Olsen

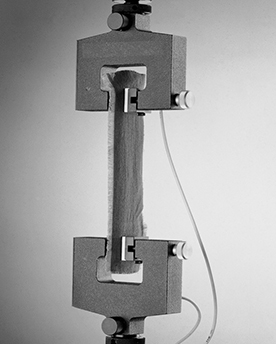

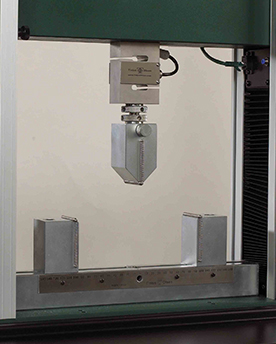

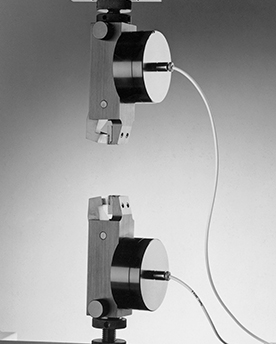

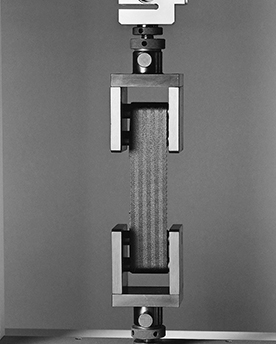

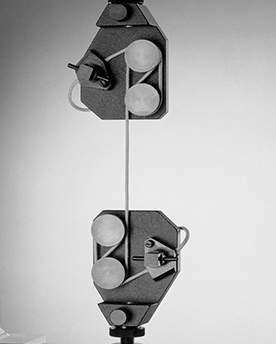

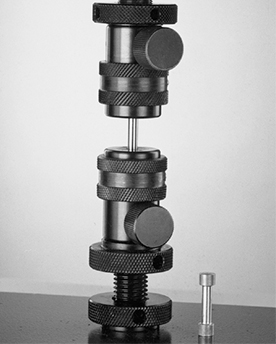

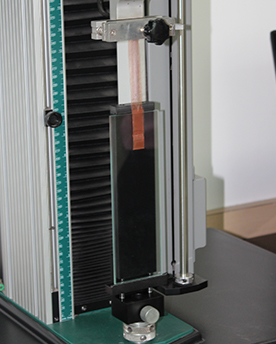

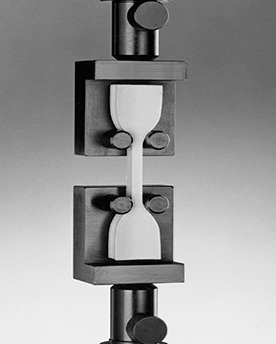

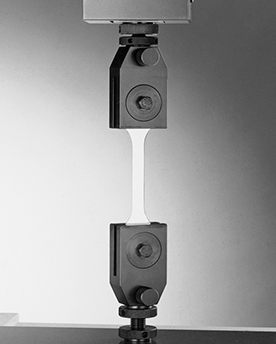

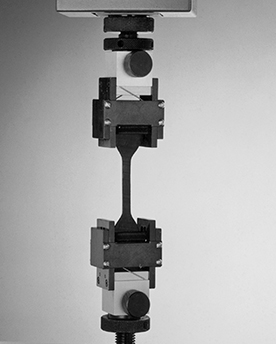

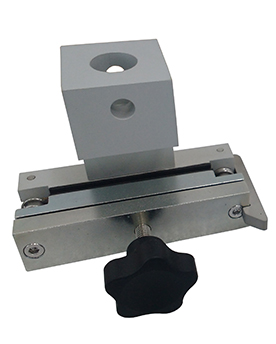

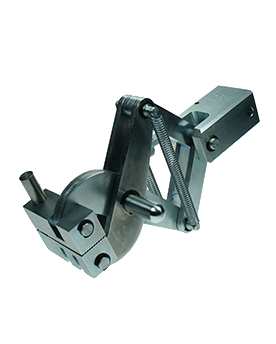

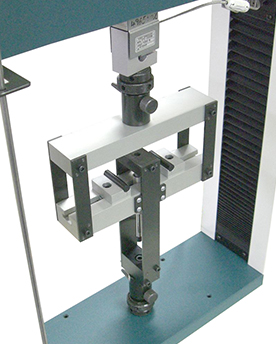

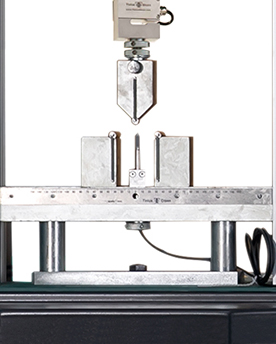

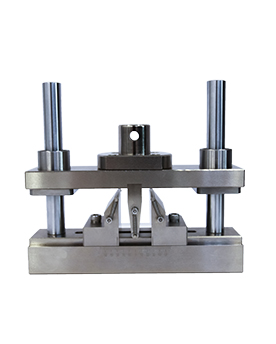

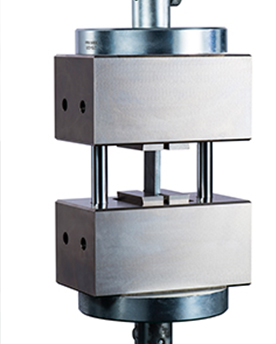

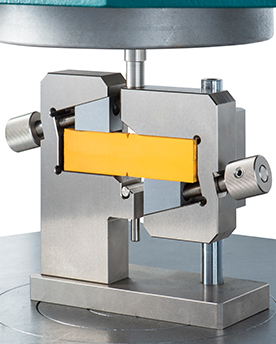

122-007 Side operating Pneumatic Grip, 5kN

Applications:

Flat flexible materials, textiles, paper, film, polymers.

Compatible with:

Tinius Olsen ST series of materials testing machines

Specifications

- Maximum capacity: 5kN (1,000 lbs)

- Minimum loadcell: 500N/li>

- Dimensions: 225mm high

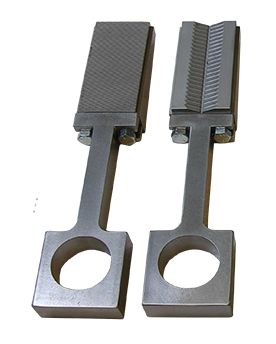

- Specimen dimension: 23mm thick (Width depends on fitted jaws)

- Weight: 7.3kg (without jaw faces)

- Maximum clamping force: 10kN (2,000 lbs) at 80psi/5.5bar

(clamping force stays constant even if sample reduces in thickness) - Operating air supply: 80-100psi / 5.5-7bar

- Temperature range: -30° to 70°C.

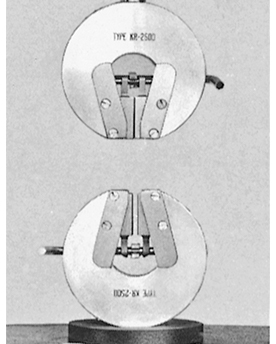

Other jaw faces are available on request.

-

Download User Instruction Manual

Please Fill the Fields to download pdf

Request a Proposal

Similar Accessories

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

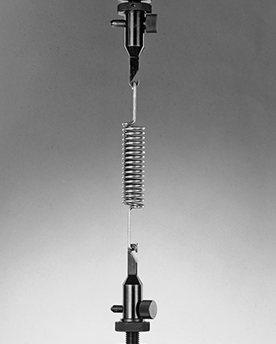

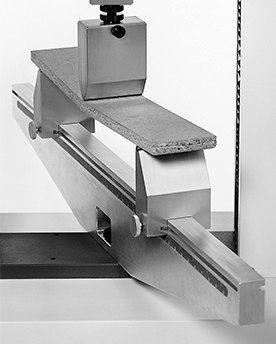

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

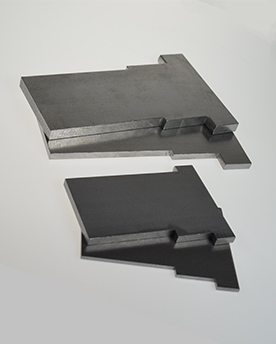

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

CA-1-21 Tensile wedge grip, 50kN

CA-1-21 Tensile wedge grip, 50kN

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

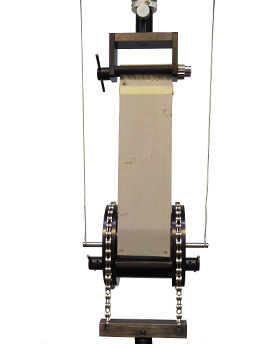

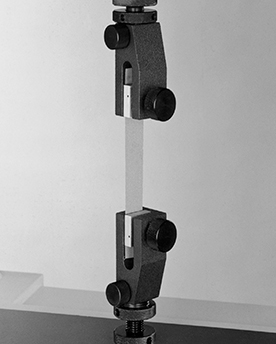

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

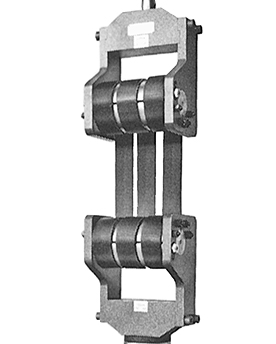

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture