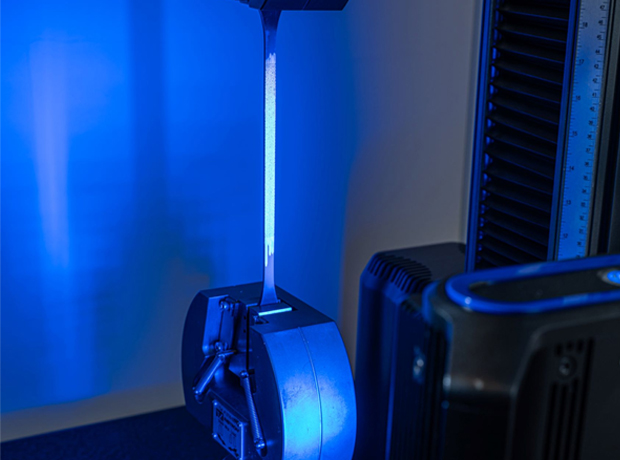

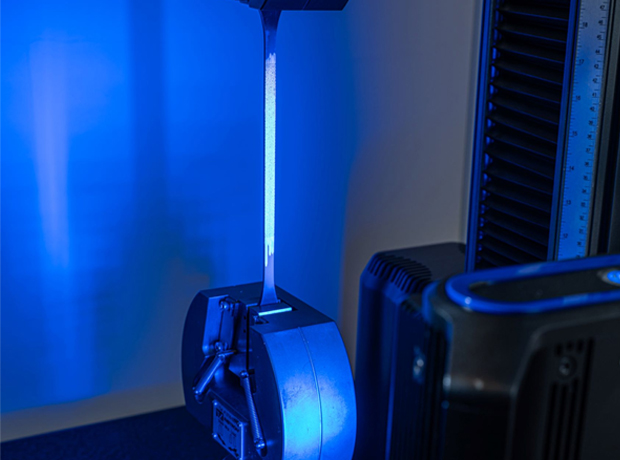

Dynamic Advanced Extensometer, Video Gauge

The UVX3D 220 non-contact video extensometer is engineered to deliver unparalleled accuracy and versatility across a wide range of testing applications. Whether you are performing tensile, compressive, flexural, dynamic or torsion strain measurements, the UVX3D 220 is equipped to meet your demands with precision. Additionally, its capability to perform out-of-plane deformations in both axial and transverse measurements opens the door to advanced calculations such as Poisson’s ratio (ASTM E132-17) and the plastic strain ratio (ASTM E517-19). Consequently, this makes it an invaluable tool for complex materials testing. UVX3D 220 suitable for out-of-plane deformations

FEATURES & BENEFITS

Exceptional accuracy and compliance

Engineered to meet the highest standards of precision, the UVX3D 220 complies with ISO 9513 Class 0.5 and ASTM E83 Class B-1 standards. As a result, your testing procedures are not only compliant with global benchmarks but also delivers the reliability and accuracy you require.

Versatile testing capabilities

With a high-resolution optical system that spans a 240mm Field of View (FoV), the UVX3D 220 is ideally suited for testing materials with larger gauge lengths or those that exhibit significant plasticity or elasticity, even in materials that exhibit out-of-plane deformations. In contrast, this extensive FoV differentiates it from the UVX3D 110 model, which offers a 110mm FoV, providing a solution tailored to your specific testing requirements.

Designed for challenging environments

The UVX3D 220’s advanced optical setup is designed to withstand challenging environments. In particular, its enhanced immunity to glare and variations in ambient lighting ensures consistent and accurate performance, even in the most demanding conditions. Moreover, the inbuilt lighting system effectively negates environmental effects, mitigates emitted radiation from high-temperature specimens and ensures accurate measurements even in the presence of out-of-plane deformations, safeguarding the integrity of your data.

Seamless integration and stability

The UVX3D 220 comes with a robust frame mounting kit, designed to integrate effortlessly with the Vector Extensometer mounting system. As a result, this compatibility ensures that the extensometer can be securely and easily attached to any test frame, providing stability throughout your testing procedures. Furthermore, the ease of installation combined with the stability of the system contributes to a smoother, more efficient user experience.

SPECIFICATIONS

Extensometer measurement applications: Uniaxial; Tensile, Compressive, Flexural or Shear Biaxial; Transverse, Dual-Average

Measurement modes: Strain (%), Extension (mm), Displacement (mm), Positions (mm), Rotation (°), Poisson’s ration, Strain map.

Field of view (Cuboid listed in mm) (Width varies with data rate): Preset: 220H x 40D x | 120 Hz: 94W | 500 Hz: 48W | 1000 Hz: 24W

Resolution: <0.5 μm

Extensometer accuracy class: Meets or exceeds ISO 9513 Class 0.5 and ASTM E83 Class B-1 capable

Gauge lengths supported: 20 to 200 mm

AE900 Automatic Extensometer

AE900 Automatic Extensometer

AEX200 Automatic Extensometer

AEX200 Automatic Extensometer

AEX500 Automatic Extensometer

AEX500 Automatic Extensometer

100R Extensometer

100R Extensometer

100S Extensometer

100S Extensometer

600LS Laser Extensometer

600LS Laser Extensometer

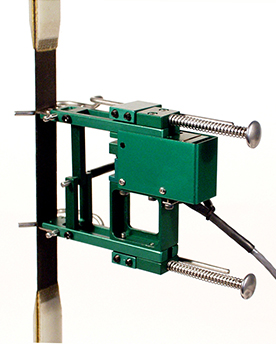

LVDT Type Extensometer

LVDT Type Extensometer

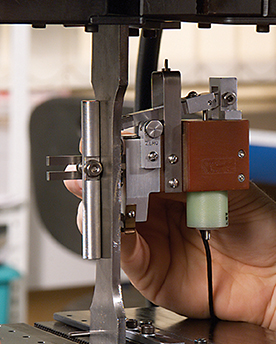

Strain Gage Type Extensometer

Strain Gage Type Extensometer

VectorExtensometer U200

VectorExtensometer U200

UVX3D 110 Extensometer

UVX3D 110 Extensometer

VectorExtensometer B80

VectorExtensometer B80