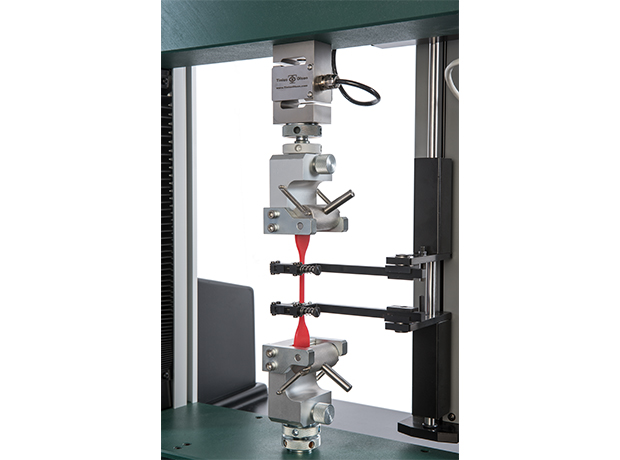

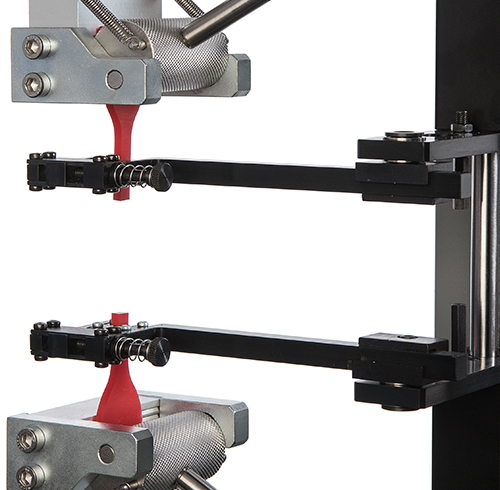

The Tinius Olsen model 100R is a high elongation extensometer that is designed to measure the ‘stretch’ of a wide range of materials including elastomers and non-rigid plastics.

The initial measuring length, or gage length, can be changed to suit the specimen size or the test standard that is being applied.

The unique design ensures an extremely low tracking force for testing sensitive materials, as well as a robust construction that can easily withstand the high release forces and breaking energies with certain specimens.

The design also incorporates a simple yet effective method by which the extensometer followers are attached to the specimen, allowing rapid throughput of testing.

Measuring Extension

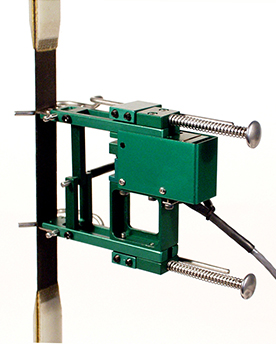

Extension is measured by attaching two counterbalanced extensometer clamps to the specimen at a pre-selected gage length.

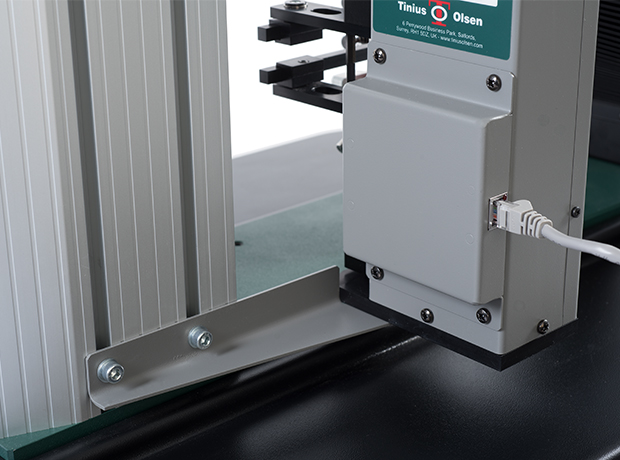

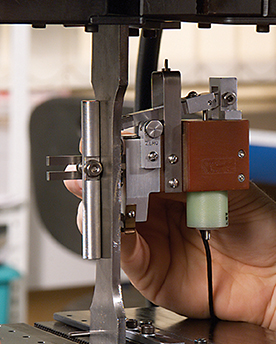

When tensile forces are applied to the specimen by the testing machine, the slightest change in gage length is measured by an optical encoder. Signals from the optical encoder are fed into the signal conditioner interface for processing.

The 100R extensometer can be fitted to all sizes of screw-driven materials testing machines.

Specifications

- Elongation measurement range: 720mm/28.35in (extended options available)

- Gage lengths: 10, 15, 20, 25, 40, 50mm

- Accuracy: 1% on 25mm gage length, ISO 5893 class A, ASTM E83 class C

- Resolution: 0.01mm/0.0004in

- Tracking force: <10g/<0.02lbf

- Specimen thickness: 0-5mm/0-0.2in

- Dimensions (HxWxD): 1015 x 53 x 200mm/40 x 2.1 x 7.9in

- Weight: 5.5kg/11lb

AE900 Automatic Extensometer

AE900 Automatic Extensometer

AEX200 Automatic Extensometer

AEX200 Automatic Extensometer

AEX500 Automatic Extensometer

AEX500 Automatic Extensometer

100S Extensometer

100S Extensometer

600LS Laser Extensometer

600LS Laser Extensometer

LVDT Type Extensometer

LVDT Type Extensometer

Strain Gage Type Extensometer

Strain Gage Type Extensometer

VectorExtensometer U200

VectorExtensometer U200

UVX3D 110 Extensometer

UVX3D 110 Extensometer

UVX3D 220 Extensometer

UVX3D 220 Extensometer

VectorExtensometer B80

VectorExtensometer B80