Tinius Olsen

Flexure

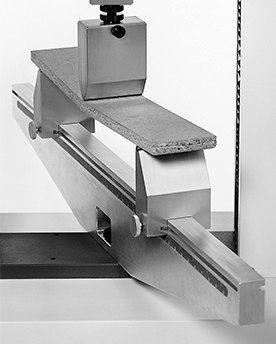

Flexure (bend) tests are commonly used to determine the flexural modulus or flexural strength of a material. A ductility test is more economical than a tensile test and the test results are slightly different. The material is placed horizontally at two points of contact (lower support span) and then a force is applied to the top of the material through one or two points of contact (upper loading span) until the sample fails. The maximum recorded force is the flexural strength of that particular specimen.

The most common purpose of a flexure test is to measure flexural strength and flexural modulus. Flexural strength is defined as the maximum tension on the outermost fiber on the compression or tension side of the specimen. The flexural modulus is calculated from the slope of the stress versus strain deflection curve. These two values can be used to evaluate the ductility of the sample material or its ability to withstand bending forces.

Unlike a compression test or tensile test, a flexure test does not measure fundamental physical properties. When a sample is placed under flexural loading, all three fundamental stresses are present – tensile, compressive and shear – and therefore the flexural properties of a sample are the result of the combined effect of all three stresses together (though to a lesser extent).

The two most common types of flexion tests are the three-point and four-point flexion bending tests. A three-point bend test consists of a specimen held horizontally at two points and force applied through one point at the top of the specimen so that the specimen is bent into a “V” shape. A four-point bend test is roughly the same except that instead of a force applied through one point at the apex it is applied through two points so that the specimen experiences contact at four different points and becomes more of a “U” shape. The three-point flexion test is ideal for testing a specific location of the sample, whereas the four-point flexion test is more suitable for testing a larger portion of the sample and is better at exposing the defects.

A bend test is similar to a flexure test in the type of hardware and the testing process involved. A bend test is used with ductile material whereas a flexural test is used with brittle material.

Typically, a flexure test is run until the specimen experiences failure and is therefore ideal for testing brittle materials. The most common materials tested for flexibility are plastics, composites, concrete and ceramics. Because these materials have very little ductility, they will break before any permanent deformation of the sample allows accurate measurement of the flexural modulus and strength.

Request a Proposal