Testing > By Materials > Fasteners

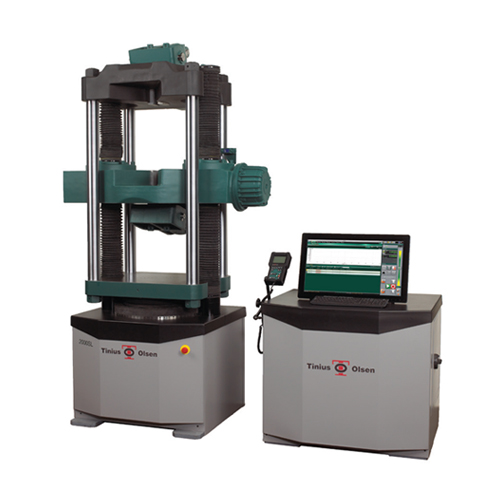

Tinius Olsen

Fasteners

Fasteners are used to mechanically attach or connect other hardware items and come in many forms including rivets, nuts, bolts, studs, screws, washers, eyebolts, nails and threaded fasteners. Fastener standards allow hardware product manufacturers, as well as end users of such products, to examine and assess fasteners to ensure their strength and quality for safe use.

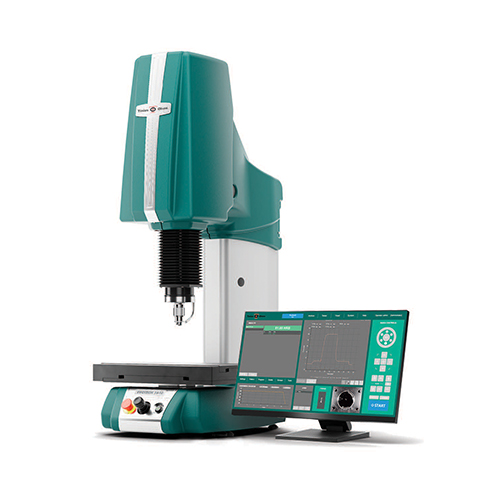

Tinius Olsen offers a wide range of fastener testing, dimensional inspection and failure analysis capabilities to ensure your business operates efficiently. Whether you order a trial to research quality issues with raw materials, finished fasteners, or production, you will benefit from identifying and repairing weaknesses or defects before they become costly problems.

Fastener testing services are comprehensive and for all types of metal fasteners. The highly trained staff has years of experience in materials engineering, metallurgy, chemistry, materials testing and metrology. Our fastener testing services are accredited and executed to industry standards including ASTM, SAE, ISO, NAS and NASM.

Tinius Olsen can determine the mechanical properties of materials such as fastener tensile strength, hardness, load capacity and more:

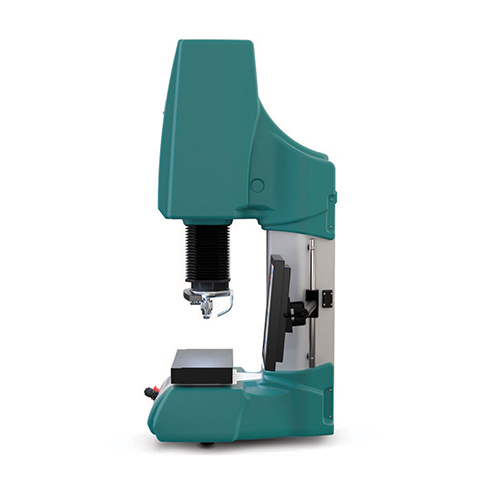

- Hardness testing

- Magnetic permeability

- Double shear

- Yield strength

- Wedge & axial Ttensile

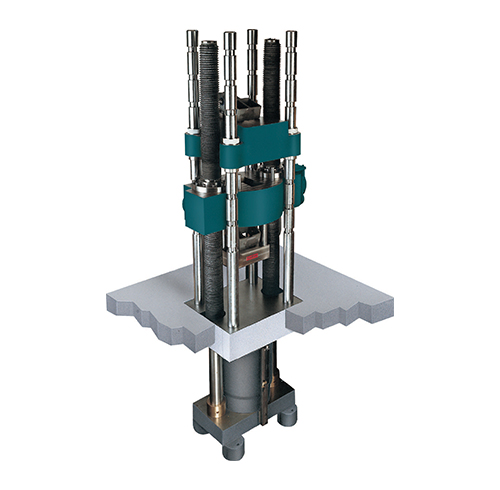

- Proof load testing

- Tension fatigue test

- Cone strip test

- Flattening

- Creep testing

- Stress rupture test

- Hydrogen embrittlement/stress durability

- Washer testing

- Free height test

- Compression

- Interlocking test

- Twist test for locking washers

Tinius Olsen provides solutions for test fasteners, including tensile strength, folding endurance, impact strength, head deformation, melt flow, puncture, and more.

Request a Proposal