Ways to Use Exported Data for Better QA Manufacturing

Data has become extremely important in manufacturing. It serves as a collection of information and statistics used for reference or analysis. When gathered from a variety of sources along the production environment, this data gives manufacturers valuable insights to help optimize the supply chain, reduce costs, and improve the quality of their products.

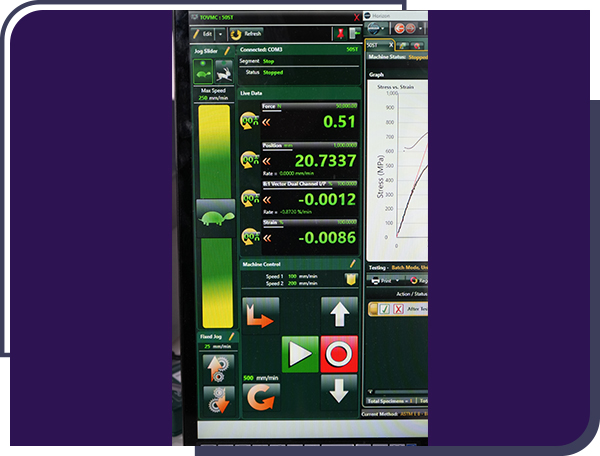

Data analytics takes this a step forward, helping manufacturers predict maintenance needs, prevent downtime, and create a safer work environment. By effectively using data in manufacturing, businesses become more sustainable and more profitable. (Figure 1)

Automation for Improved Testing Efficiency

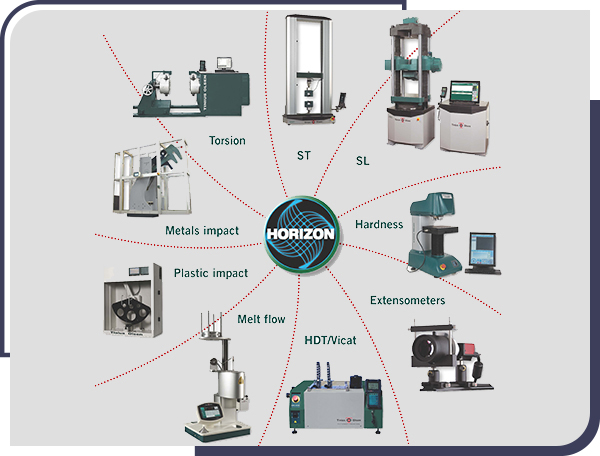

By running tests continuously or in parallel, often 24/7, automated materials testing is far more reliable than manual testing. It improves testing efficiency by ensuring consistent, repeatable test parameters and reducing errors. The larger datasets generated by an automated materials testing system provide better, more reliable insights, while offering traceability and reproducibility. (Figure 2)

In its Digital Maturity Index 2023, Deloitte “found that 98% of 800 surveyed manufacturers in four major global economic regions have started their digital transformation journey, compared with 78% in 2019, and respondents reported cost optimization, operational efficiency, product innovation, and improving customer experience as key drivers for the shift.”

But how do these systems collecting and exporting data provide better quality assurance manufacturing? And how has the availability of that data improved manufacturing environments?

Data Access Made Easy

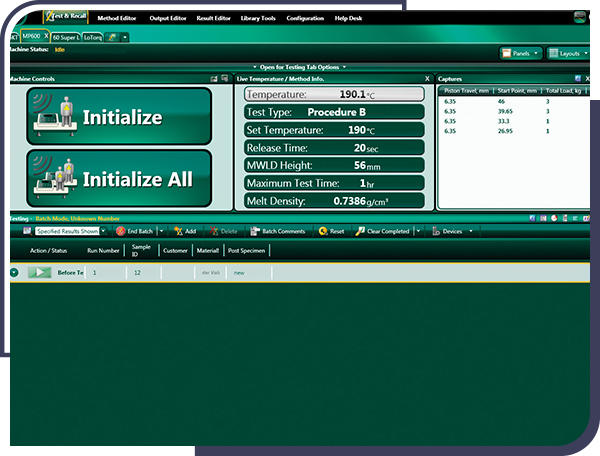

As the digital infrastructure continues to grow, working with the data gathered during test, whether for the demanding rigors of R&D or the charting and analysis functions of QC testing, is critical to modern materials testing. Horizon software from Tinius Olsen, for example, offers an intuitive interface, providing quick access to a number of usability and access points, such as:

- Test method library

- Test editor

- Tabbed test and recall area

- Multiple machine control

- Output editor

- Method editor

- Result editor

- Multifaceted security

- Data importing

- Report consolidation

- Webcam functionality

This ease of gathering and analyzing data improves the manufacturing environment by enabling the collection, processing and analysis of statistically meaningful information that can help direct quality control and production efficiency.

The advanced, data-centric environment provided by the Horizon software delivers a powerful, adaptable interface that supports both research-intensive development and standardized quality assurance work to meet the evolving needs of materials testing. The platform can be used integrated into virtually any materials testing environment.

Putting Unprecedented Data Insights into Action

A typical data collection program will offer a variety of different graphs that can be produced per test, once all data has been gathered. But today’s data collecting and analysis methods can go much, much further relying on data across the continuum, from live data on a currently uploaded specimen to historical data obtained through several previous test iterations. (Figure 3)

In addition to accessing live data during testing, acceptable limits of the results can be selected as well. The results can be viewed graphically in multiple formats and customized for user-specific reporting. Unique results can be calculated from parameters and from other tests and equipment. Information can be exported to a variety of different formats, making data gathering and reporting seamless.

Following International Test Standards

If your testing regimen follows a quality control analysis to a variety of international standards, make sure you enlist a software program with a test method library that has been written in accordance with different international test standards, including ASTM, ISO, EN, BS DIN and more.

It should also allow for customized test setup, using a standard as a template, and be offered in multiple languages and dialects as well as with an option for users to create test method, giving them complete control over how the test machine performs throughout the course of the test. This will also help give you a wide variety of data to match your materials testing needs.

For example, the Horizon platform can convert hardness values into five different hardness (and tensile) scales simultaneously according to international standards (ISO/ASTM). For a global company where materials are tested at various locations, each follows different testing standards. If the same material is to be used across all sites, but the required validation varies according to local standards, different hardness scales may be needed.

For instance, the QA facility might follow ASTM standards requiring Rockwell hardness, while another location adhering to BS standards may specify Brinell hardness for the same material. In such cases, repeating the test in every scale is redundant — instead, the material can be tested once and the results converted using conversion function in Horizon, allowing the report to include equivalent hardness values across all relevant standards.

Conclusion: How is Data Used in Manufacturing?

The innovative use of data in manufacturing appears to be a stabilizing force for the global manufacturing industry. Data helps to predict future outcomes using both current analytics and historical data. This advanced methodology helps to decode complex manufacturing processes and improve materials testing outcomes.

Collecting data on the quality of a specific part can be helpful for auditing production processes and ensuring that work is standardized, as well as helping to reduce waste.

Materials testing analytics improve product quality by capturing machine-level information, boosting production yield and throughput. Data that shows the cost and effort involved in developing products helps quickly identify problems and predict issues. This aids in quality production, while significantly reducing costs. The use of data in manufacturing environments, especially in materials testing, has become a pinnacle of operational improvement.

For a deeper dive into using data in your materials testing environment, check out our white paper on Integrated Data Analysis Improves Efficiency in Materials Testing