Tinius Olsen

Peel

Peel strength is commonly used to measure the adhesive strength between two flexible substrates or the bonded surface of a flexible and rigid substrate. Flexible substrates often consist of tape, film, thin plastic materials, rubber or other polymers, while rigid substrates are usually not limited to one type of metal, rigid plastic, or composite. The conditions under which these materials are tested are composed of various combinations of pre-treatment, temperature and test speed depending on the standard test method used to guide the test procedure.

Peel strength is the average load per unit width of the bond line required to separate the bonded material where the angle of separation is 180°.

A peel test is performed between two substrates bonded with an adhesive. The substrate can be both flexible or one can be flexible while the other can be rigid. Adhesive usually takes the form of a thin layer between two substrates such as an adhesive placed under a piece of tape that has been placed against a steel plate.

Typically the goal of a peel test is to determine the adhesive strength of the material or the strength of the adhesive bond between two materials. This adhesive strength may be referred to as the “stickiness” of the material as it is a measure of the resistance of specimens to separate from each other after the adhesive is applied. This measured value can be used to determine whether the adhesive bond is strong enough or too strong for the application and whether a different adhesive or bonding process is needed.

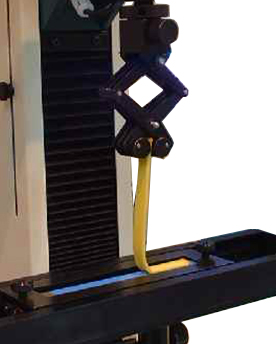

The most common types of peel tests to measure adhesive strength are T-peel, 90 degree peel, and 180 degree peel. T-peel test is a type of tensile test which is performed on two flexible substrates which are bonded together and held in the peel test grip such that one substrate sticks and the other sticks while the bonded area is horizontally Sticks so that the whole setup forms a “T” shape. The 90 degree test fixture is required to determine the adhesive strength between a flexible (tape) and rigid substrate (plate) where the plate sticks vertically with the holding end of the tape horizontally. Give the plate an “L” shape while the rest is tied. The 180° test is similar to the 90° peel test, except that the bonding area between the tape and the plate is held perpendicular to the peel test grip while the free end of the plate is held down and the free end of the tape. The top is gripped so that it forms a tight “U” shape.

Tinius Olsen provide force measurement equipment and material testing machines for peel testing. All testing hardware is fully complemented by our Horizon software.

Request a Proposal