Tinius Olsen

Impact

An impact test is used to observe the mechanics that a material will display when it experiences a shock loading that immediately causes the specimen to deform, fracture or break completely. To perform this test, the specimen is placed in a holding fixture with geometry and orientation determined by the type of test used and then a known weight (not usually in the shape of a pendulum, so that it strikes the sample with a sudden force) is released from a known height. This collision between the weight and the sample usually results in the sample being destroyed but the transfer of energy between the two is used to determine the fracture mechanics of the material.

The purpose of an impact test is to determine the ability of a material to absorb energy during a collision. This energy can be used to determine the material's hardness, impact strength, fracture resistance, impact resistance or fracture resistance, depending on the test used and the characteristic to be determined. These values are important for the selection of materials that will be used in applications that require the material to undergo very rapid loading processes such as in vehicular collisions.

The three most popular types of tests for a single impact are Charpy V, Izod and tensile impact. These three tests determine essentially the same characteristics of the material, but differ in the orientation of the test specimen, which causes the specimen to strain in different directions and involves a known weight released from a known height that collides with the sample in its test fixture. All these tests are useful in determining the impact mechanics of the test specimen.

Almost all materials can benefit from impact testing, but the most common types used are metals, plastics, wood, composites, ceramics and polymers. These materials generally take the form of sheets of different thicknesses or smaller rods, depending on the test. However, most materials will experience either ductile or brittle failure depending on the type of test, the rate of loading and the temperature of the sample. A small amount of energy is required for the brittle failure of the material to initiate the crack or for the crack to grow until the sample fails. On the other hand, a very high load is required to initiate the tensile failure of a material and propagate the crack until failure.

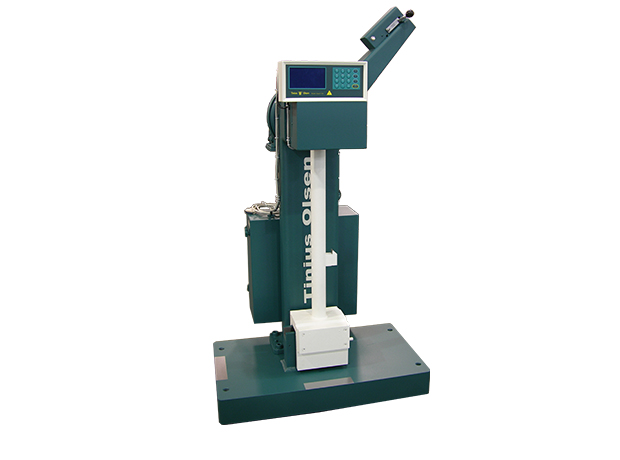

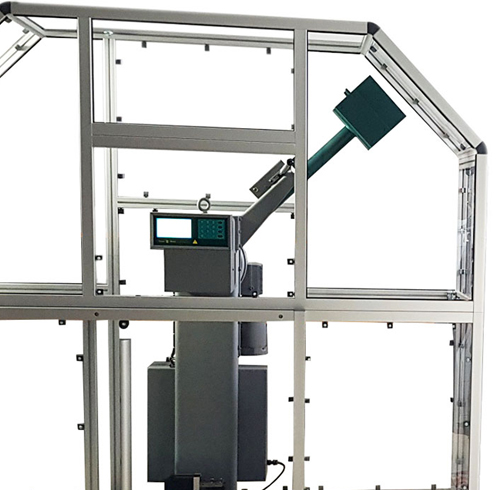

Tinius Olsen offers both high and low energy pendulum impact systems. Most systems are easily changed from a Charpy to Izod configuration. The pendulum impact systems come in various capacities up to 800J and are primarily used to determine the impact resistance of materials while complying with international standards.

The pendulum impact systems offer various features and accessories that ensure safe and reliable testing while maintaining accuracy and repeatability of results. Features include motorized return, braking systems and lower capacity testing within the machine range, according to which machine is selected.

Tinius Olsen provides force measurement equipment and material testing machines for impact testing. All testing hardware is fully complemented by our Horizon software.

Request a Proposal