New Extensometer Technology Facilitates Better Materials Testing

With tight timelines and even tighter budgets, the pressure to deliver high-caliber products has never been more important. In a world where quality and reliability can make or break a company’s reputation, cost-effective testing techniques that improve testing efficiency and benefit from modern technological advancements are the ones that will give R&D, engineers and test facilities a distinct advantage.

Since the standardization of extensometry in the 1950s, the use of an extensometer—a sophisticated ruler used to measure displacement or strain on the surface of a test piece—has not changed significantly. However, it has become evident that this testing methodology needed a boost to keep pace with modern applications, where other computing mechanisms have been built into materials testing systems.

Increased Test Efficiency

The introduction of new optical extensometer technology has made traditional, mechanical tools nearly obsolete. It uses intelligent non-contact, high-accuracy measurement techniques to eliminate the common challenges of traditional contacting and non-contact extensometers, while also offering some distinct advantages.

For those looking to take an easy, first step toward automating their existing materials testing process in order to maintain consistency in test performance, the new Vector Extensometer (Figure 1) reduces operator involvement, decreasing manual errors in calculation or calibration as well as simultaneously measure longitudinal and transverse strain.

This self-contained, plug-in-and-power-up precision system eliminates all the tricky and cumbersome set-up options associated with other optical extensometers and removes the need for multiple PCs and interface equipment.

Using adaptive Artificial Intelligence (AI) coupled with optical hardware, Vector reduces testing time and is ideal for complex environments, such as assessing extremely fragile specimens as well as small and non-uniform specimens, measuring strain through failure or operating in harsh or dimly lit applications.

Tackling Common Trouble Spots

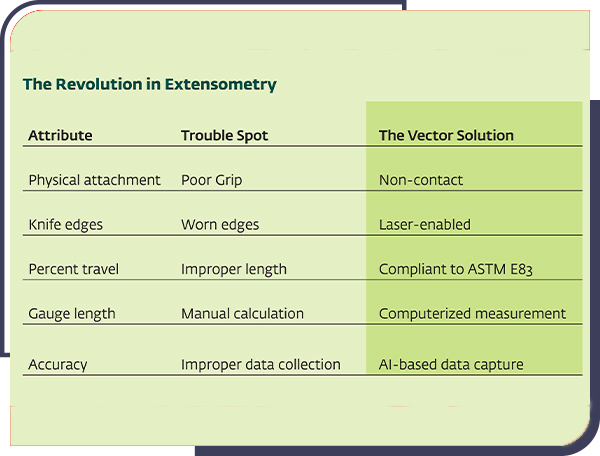

For each trouble area that extensometry has encountered in the past, now there’s an easy solution.

Poor grip on a specimen? Vector is non-contact. Worn edges? No problem, Vector is laser-enabled. Improper length? It is compliant with ASTM E83. The need for manual calculation? Measurements are now computerized. Worried about accuracy and the possibility of improper data collection? AI-based capture eliminates that risk.

Vector addresses it all, clip sensitivity, dulled edges, physical marking, manual calibration fluctuation, non-uniform specimens, synchronized force and strain data. It delivers quality results in every test. (Figure 2)

Adoption and Usability

Setup is straightforward, so adding it to existing equipment is simple. And what is even better, there are no special skills required to run it. Everyone from new hires to company veterans can set up the machine and start running tests in no time.

Vector reduces risk because it is very hands off and streamlined, with processing power contained within the unit itself. Users don’t need a separate PC to process and manage the data. The system pre-processes it and sends direct to the main PC.

This cutting-edge technology is the very latest in digital extensometry, enabling synchronized force and strain data in real-time, with no lag.

Optimal ROI

This step-change in digital, data-driven materials test processing is seen across a wide range of industry sectors, with Vector meeting or exceeding ISO 9513 Class 0.5 and ASTM E83 Class B1 standards. Vector provides optimal overall ROI, thanks to its streamlined testing process, accurate results in every test scenario and the elimination of consumable parts that need replacement.

Accuracy, resolution, data rates, control, precise adherence to test standards, calibration, measurement of uncertainty and traceability – this new advancement in extensometry can handle them all.

To learn more about available Vector models and how new optical extensometer technology facilitates better materials testing, download our whitepaper Modern Extensometry for a Data-driven World.