Recent Shifts in Melt Flow Indexing

Over the past several years throughout the automotive, packaging, healthcare and electronics industries, the demand for plastics and polymers has been on the rise, increasing the frequency and use of melt flow testing across most manufacturing environments. Each industry must follow stringent quality control guidelines, as put forth by ASTM and ISO, to gauge precise measurements of melt flow properties, maintain quality control and establish consistent product development processes. (Figure 1)

Melt flow testing’s critical role helps determine the flow properties and viscosity of plastics and polymers in a variety of production applications. Melt flow index (MFI) testers are one of the staple materials testing systems companies use to meet the widely accepted ASTM 1238 D-23a and ISO 1133-1:2022 standards as well as comply with specific industry regulations.

Melt Flow Testing Basics

Manufacturing processes have different requirements based on the production method being used, the material being processed and the intended final product, but the melt flow test process is basically the same:

- Test Preparation: a known quantity of polymer granules is added to machine’s barrel

- Polymer Melting: polymer is heated to a specific, consistent temperature

- Load Applied: Force is applied to the piston (physical weights or via load cell)

- Polymer Extruded: Molten polymer is pushed through a die

- Extrusion Measurement: extruded polymer is collected over a specified period

- MFI Calculation: value is determined based on the extruded polymer weight and timeframe

The standard units to express the MFI calculation – typically g/10 min for melt flow index MFR or cm³/10min for volume flow index MVR (ASTM/ISO) – remain the same, allowing for consistency and comparability across different materials and testing conditions.

What MFI Testing Systems are Available?

Traditional melt flow indexers employ a set of physical dead weights that are either manually or automatically placed on the machine for testing. This type of system is best suited for applications with a stable environment, where load, temperature, and material composition don’t change.

However, most manufacturing facilities as well as research labs, universities and third-party testing companies need to accommodate at least some variables in the melt flow testing process.

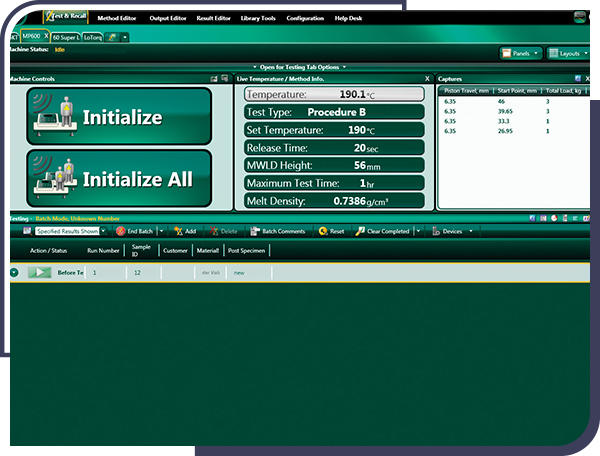

Load cell-based MFI systems are key in today’s materials testing environments to enable quick and easy modifications to test set ups. These systems also deliver far more precision, control, measurement, and available data for streamlined calibration as well as improved testing efficiency and operator safety across the MFI test process. (Figure 2)

A closed loop system, like the MP1500 Loadcell Melt Flow Indexer, will detect small variations in flow that a conventional weighted system may miss and can measure the sensitivity of force across the entire test for higher accuracy in the results. It works with closed loop, where load is applied by a motor and ball screw system with a PID (proportional integral derivative) control feedback. With no dead weights, human error is reduced and results across different labs and operators are more repeatable and consistent.

Integrated sensors enable real-time tracking of melt viscosity and flow behavior during extrusion as well as continuous monitoring of piston position, load, and displacement, and even rapid data logging and analysis.

Operators can configure machine options and program user settings (language, units, alarms, etc.) from an integrated display interface as well as set and store individual test protocols for rapid recall. The unit can be controlled via the touchscreen when combined with a comprehensive software suite, like Horizon, the equipment becomes a test system powerhouse, improving overall manufacturing operations through shared data and advanced analytic capabilities. (Figure 3)

Emerging Markets and Industry Needs

Load-cell based melt flow test systems are gaining popularity across a wide range of industries, from manufacturing, compounding, and packaging to automotive, medical, 3D printing, and recycling. By providing greater accuracy, automation, flexibility, and efficiency, these systems are instrumental in modern quality control labs and R&D environments as well as where precise material control and consistency is required.

As the use of plastics in these industries continues to evolve, there will be a steady growth in the need for melt flow testing. Technological advancements and efficient processes will be paramount in ensuring new applications and production environments maintain the level of quality performance demanded of today’s plastics and polymer resins and powders.