Integrated Data Analysis Improves Efficiency in Materials Testing

You Will Learn How To:

- Make data more actionable and accessible

- Speed up testing and reporting capabilities

- Ensure adherence to the latest industry standards

- Facilitate better operational efficiencies

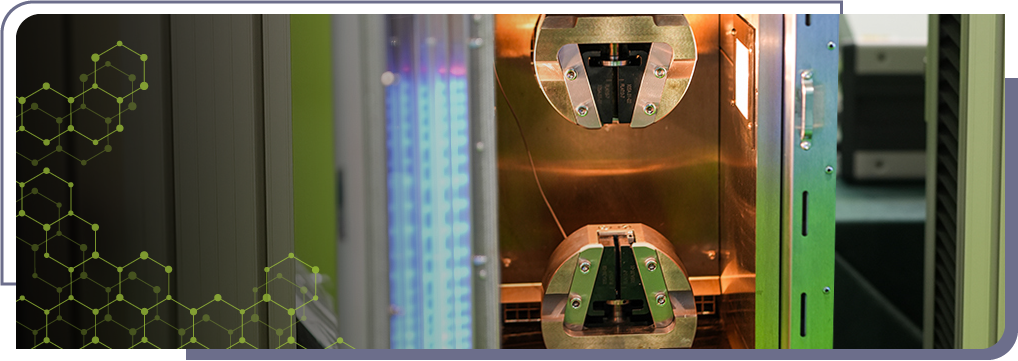

By creating a holistic approach to material testing, intuitive software platforms are cohesively managing the complex data sets generated by today’s material testing equipment. Instead of siloed environments, comprehensive software suites are driving business value and operational efficiencies through greater visibility within test results.

A testing infrastructure that uses a modern software platform provides enhanced data analysis to enable critical insights, such as statistical analysis, trend identification and predictive modeling, as well as help improve how material properties and behavior are evaluated.

Overview

This white paper reviews how Tinius Olsen’s user-friendly, universal Horizon material testing software platform improves overall manufacturing operations through shared data principles and advanced analytic capabilities. It also outlines the benefits of simplified reporting and an easy user interface to provide improved testing analysis and actionable intelligence.