Blogs

Challenge the Naysayers in Engineering Design

The engineering design field has witnessed a multitude of profound changes and emerging trends in the past decade with digital...

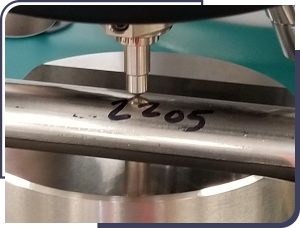

New Extensometer Technology Facilitates Better Materials Testing

With tight timelines and even tighter budgets, the pressure to deliver high-caliber products has never been more important. In a world where...

Automotive OEMs Improve Materials Testing ROI With In-house Infrastructure

Materials testing is an integral part of the automotive industry. It provides quality assurance by ensuring that vehicles, including all...

Two Test Systems, One Software Platform

Technology innovations in materials testing aren’t just providing better data analytics, they are also providing improved testing...

Sustainable Alternatives Gain Validation Through Materials Testing

The past few years have shown us that the world around us is finite and fragile. And we all play a part in its sustainability. There has...

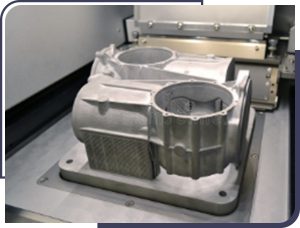

Elevated Temperature Testing Validates Innovation in Additive-based Superalloy Manufacturing

Commonly used in extreme environments, such as in the aerospace, industrial and power generation markets, superalloys are a class of...