Challenge the Naysayers in Engineering Design

The engineering design field has witnessed a multitude of profound changes and emerging trends in the past decade with digital transformation in full swing. As companies harness available technologies and leverage design innovation and products to enhance business capabilities and customers’ experience, engineers are facing new and complex challenges to adapt processes and ensure product reliability.

This rapid growth of technology is reshaping the way engineers design and develop equipment as they look further into the future to ensure compliance for quality testing of products to meet both existing and evolving standards.

Thanks to this, the role of engineering redesign and quality testing has become more crucial than ever. And while some may think these new challenges merely pose stumbling blocks, we see them as ways to improve the role of materials testing across all applicable industries.

Maintain Design Integrity

Engineers are confronting more instances of solving design problems due to the rapid speed at which technology is advancing. For materials testing, this presents some unique challenges, as engineers also must meet specific industry standards for safety, quality and production requirements. There is a careful balance between the innovation happening within their production environments and the need to adhere to existing industry standards.

Lexi Patania, mechanical design engineer for Tinius Olsen, noted, “Some may believe that, with new technologies comes new machinery, and that is true to an extent. But many aspects of the development and testing process can be redesigned and adapted to meet new technical challenges.”

She goes on to explain, “There are often scenarios, where the dimensions of a specimen, or it’s expected force, may fall outside the range our normal test fixture accepts. That involves adapting the current fixture to meet the required dimensions and load capacity, as well as any other design constraints. We do a lot of that, but we’re also very involved with developing new designs to meet the growing complexities we see in our customers’ applications, while maintaining much of the existing test infrastructure.”

New Challenges Mean Opportunities

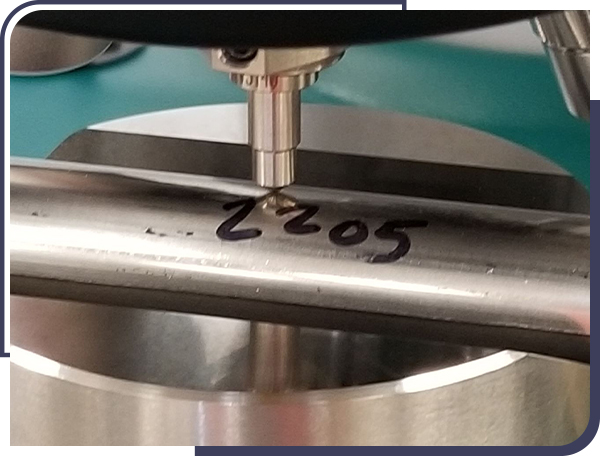

Patania explained a recent project for hardness testing, which typically uses a flat or v-anvil fixture when testing typical Rockwell specimens.

This particular application, though, involved a specimen with complex geometry and several different testing locations along its length and rotational axis, all of which needed support, directly through each of the test points. Because each test point had different geometric attributes, and the sample must be fixed when load is applied, the fixture needed to be adaptable in one linear and one rotational motion, and lock in place at all 16 positions.

She continued, “We were able to develop a fixture that tests 4 points, turns once to accommodate testing of the other 4 points, and is interchangeable with a similar fixture to obtain the remaining 8. This design requires minimal operator effort, pinpoints exact test locations, and provides the results needed across the entire specimen in a way that had not been done before. It’s exciting to solve these challenges for our customers.” Identifying and solving testing problems according to set industry standards is a large part of the innovation at Tinus Olsen. (Figure 1)

Consistency Ensures Reliability in Innovation

Standards are essential to fueling innovation as well as maintaining a level of confidence in products. The integrity of broad-based frameworks establishes accurate and workable principles for technology adoption and interoperability. The research and development (R&D) stage, especially, plays a key role in meeting the constant innovation of engineering as well as adjusting standards to meet changes.

As ASTM notes, testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical and metallographic properties of certain materials…to allow metallurgical laboratories, manufacturers, and other producers…to examine and evaluate such materials for strength and quality to ensure safety towards their end-use.

Adopting Reengineered Solutions

The critical role that standards from organizations like ISO and ASTM play in the materials testing industry is undisputed. For decades, these standards have served as our barometer of product quality and customer assurance. Our next step as an industry is to facilitate the alignment of the standards with the engineering redesigns being developed that are solving the new challenges we are seeing in manufacturing and product testing. (Figure 2)

Engineering redesign has become more prevalent in the past few years as supply chain issues have grown more prominent. By practicing engineering redesign tactics, the industry can keep up with growing technologies, while still providing quality products to consumers. Have an engineering challenge you want us to take on? Check out our Service & Support page for your local contact.